You can choose our matching servo drive products, which will help you to quickly put into production

Why Choose Us

We will specifically optimize the functions and performance of our products based on the customer’s equipment conditions. The customer does not need to make additional modifications to the mechanical equipment. This is our personalized customer service.

From order confirmation, production scheduling, quality inspection to logistics shipment, we set clear time nodes and responsible persons for each link, and use SOP (standard operating procedures) to ensure that products are delivered to customers on time.

We are well aware that cooperation is not a one-time service, but a process of continuous optimization. Through service details, we make customers feel that they are highly valued.

The company provides technical services 24/7. If the problem cannot be solved through telephone or other communication methods, we will send engineers to the customer’s site to solve the problem and ensure that the customer can operate normally.

About Us

Innovation driven provider of industrial automation and new energy solutions

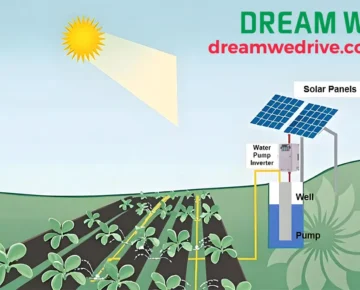

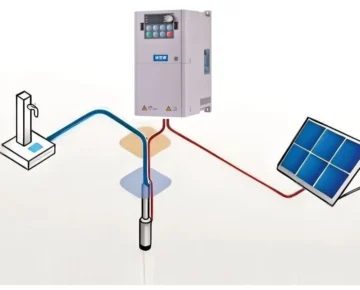

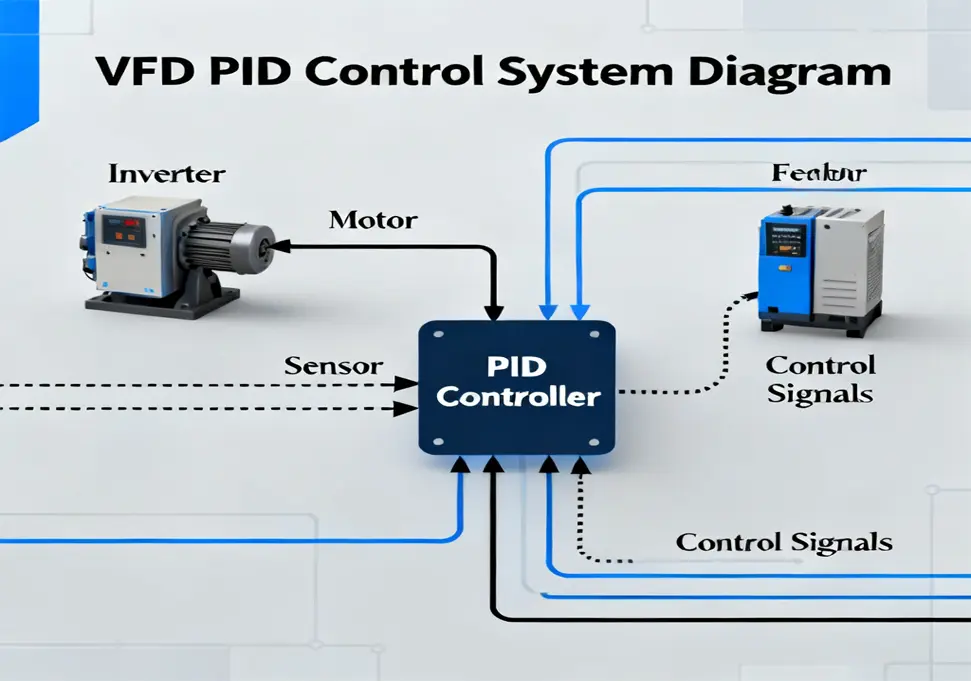

DreamWe As a high-tech enterprise specializing in servo systems, variable frequency drives, and solar pump inverters, DreamWe has built a full chain capability from core component research and development to overall solutions with “technological innovation” and “customer value” as the dual engines. The company was jointly founded by technical elites from industry leaders such as Huawei, Huichuan Technology, and Emerson. The team integrates cutting-edge experience in various fields such as automation control, power electronics, and new energy technology, forming a core advantage that combines technological foresight and engineering implementation capabilities.

The founding team members have led the development of Huawei’s industrial automation product line, Huichuan servo system, and Emerson’s new energy solution design, with an average of over 15 years of industry experience. They have deeply integrated the R&D management system and innovative methodology of leading enterprises into the entire product development process.

120 +Employees

Looking for properate products?

Contact us