How Does a VFD Work? A Simple Guide to Variable Frequency Drives

A VFD (Variable Frequency Drive) is an electronic controller that adjusts the speed of an alternating current (AC) motor by modifying the frequency of the electrical power supplied to it. This technology is widely used in industrial, commercial, and residential applications to optimize motor performance and reduce energy consumption.

A Step-by-Step Breakdown of How a VFD Works

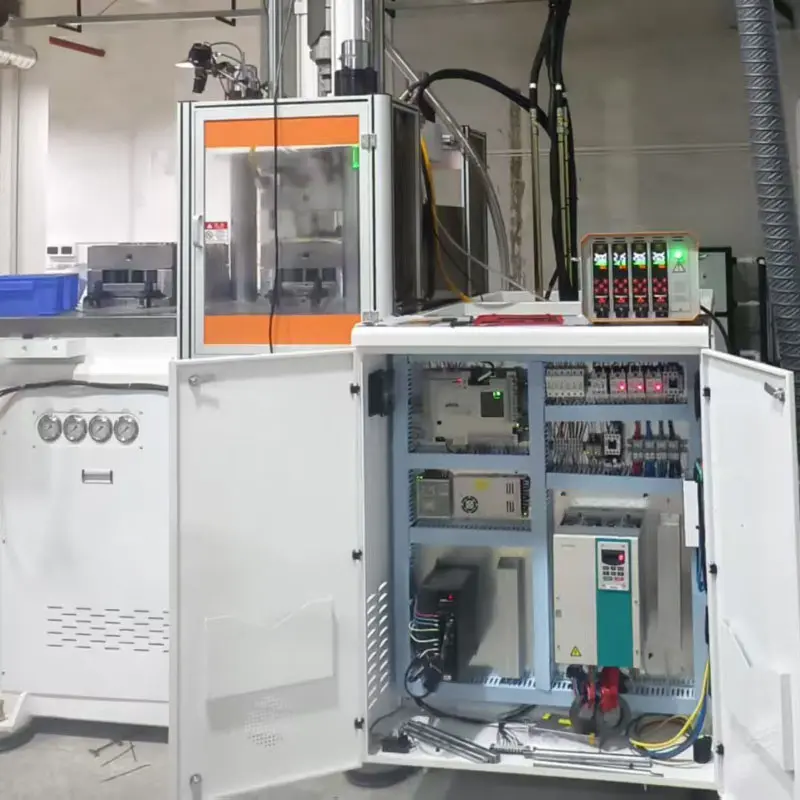

VFDs operate through three core stages, plus additional control components, to regulate motor speed effectively:

1. Rectifier Stage

The incoming AC power (from a standard electrical grid) is first converted into direct current (DC) using semiconductor devices like diodes or thyristors. This conversion process creates a “DC bus”—a temporary storage point for the converted electrical energy.

2. DC Bus Stage

A set of capacitors in the DC bus smooths out fluctuations in the DC voltage. These capacitors act like a reservoir, ensuring a steady, consistent flow of DC power to the next stage of the VFD.

3. Inverter Stage

Using fast-switching transistors (such as IGBTs—Insulated Gate Bipolar Transistors—or MOSFETs—Metal-Oxide-Semiconductor Field-Effect Transistors), the VFD converts the steady DC power back into AC power. Unlike the original grid power, this output AC has adjustable frequency and voltage—the key to controlling motor speed.

4. Motor Control Logic

By varying the frequency of the AC power sent to the motor, the VFD directly changes the motor’s rotational speed (since motor speed is proportional to power frequency). To maintain optimal motor performance, the VFD also adjusts the voltage in tandem with the frequency—a method known as V/Hz (Voltage-to-Frequency) control. This keeps the motor’s magnetic field at the correct strength, preventing inefficiency or damage.

5. Control Circuitry

A built-in microprocessor runs specialized algorithms to manage the VFD’s operation. It regulates critical parameters like speed and torque, and includes protective features to safeguard the motor from issues such as overloads, overvoltage, undervoltage, and overheating.

Key Benefit of VFDs: Energy Savings

The primary advantage of using a VFD is significant energy savings. Most motors do not need to run at full speed at all times—for example, a fan or pump may only require partial speed during low-demand periods. A VFD ensures the motor uses only the amount of power needed for its current task, rather than wasting energy at full speed. This can reduce energy consumption by 20% to 50% in many applications, lowering utility costs and environmental impact.