Harmonic Effects on VFD Motors: Causes, Impacts & Suppression Solutions

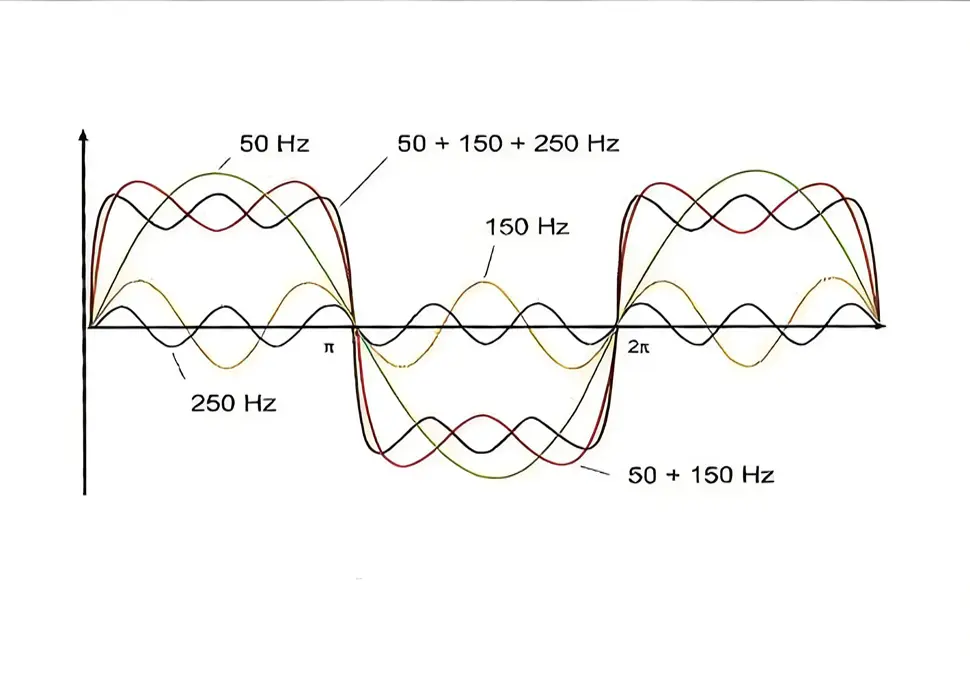

Harmonics are voltage/current components in the power grid with frequencies that are integer multiples of the fundamental frequency. Generated by nonlinear loads such as Variable Frequency Drives (VFDs), they exert multi-dimensional negative effects on the operational performance, service life, and efficiency of motors (especially induction motors), as detailed below:

I. Deterioration of Core Performance and Efficiency

-

Significant Increase in Copper Loss and Iron Loss

- Copper Loss (Winding Loss): Harmonic currents generate additional Joule heat, and the loss is proportional to the square of the current frequency (Formula: \(P_{cu} \propto f^2\)). High-frequency harmonics cause a sharp rise in winding temperature.

- Iron Loss (Core Loss): Divided into eddy current loss and hysteresis loss. Eddy current loss is proportional to the square of the frequency, while hysteresis loss is approximately proportional to the frequency. Harmonics accelerate the alternating frequency of the core magnetic field, intensifying core heating and reducing the motor’s energy conversion efficiency.

- Practical Impact: When the motor’s input power remains constant, its output power decreases, and efficiency may drop by 5%-20% (depending on harmonic content), leading to increased operational costs.

-

Torque Ripple and Unstable Speed

- The interaction between harmonic magnetic fields and the fundamental magnetic field generates “negative sequence torque” and “pulsating torque”: Negative sequence torque hinders motor rotation and reduces effective output torque; pulsating torque causes periodic speed fluctuations, resulting in vibration and noise, which impairs the precise control of motors (e.g., speed regulation in production lines, stable flow control of pumps).

II. Increased Mechanical Wear and Shortened Service Life

-

Aggravated Vibration and Noise

- If the harmonic frequency is close to the motor’s mechanical resonance frequency, resonance will occur, leading to a sudden increase in vibration amplitude. Long-term operation may cause mechanical failures such as bearing wear, rotor eccentricity, and frame loosening.

- High-frequency harmonics also produce electromagnetic noise, which overlaps with mechanical vibration noise, deteriorating the working environment. This also reflects an imbalance in the electromagnetic forces inside the motor, accelerating component aging.

-

Accelerated Insulation Aging

- Harmonic voltages increase the electric field strength borne by the motor’s winding insulation. In particular, overvoltages formed by the superposition of multiple harmonics may exceed the withstand voltage limit of the insulation layer, leading to insulation breakdown or partial discharge.

- High temperatures caused by harmonics accelerate the oxidation and aging of insulation materials (e.g., enameled wire insulation layers), shortening the motor’s insulation life and increasing the risk of short circuits.

III. Elevated Risk of Electrical System Failures

-

Rotor Overheating and Additional Losses

- For induction motors, harmonic magnetic fields induce high-frequency currents in rotor bars and end rings, generating additional “rotor copper loss” and causing the rotor temperature to rise. High temperatures can soften the welding joints between rotor bars and end rings, and may even lead to welding failure.

-

Interference with Protective Devices

- Harmonic currents may cause misoperation of protective devices such as overcurrent relays and thermal relays (e.g., false overload judgments) or failure due to inaccurate detection of actual current after harmonic filtering. This prevents timely responses to real faults, expanding the scope of equipment damage.

-

Impact on Auxiliary Equipment Operation

- If auxiliary equipment supporting the motor (such as cooling fans and oil pumps) is directly powered by the power grid, harmonics will reduce their efficiency and increase heat generation. If connected coaxially with the motor, motor speed fluctuations will affect the cooling/lubrication effect of the auxiliary equipment, further exacerbating motor overheating.

IV. Synergistic Impact on VFD-Motor Systems

- If the motor is mismatched with the VFD (e.g., the motor is not designed for variable frequency use), the negative impacts of harmonics will be amplified. For example, when ordinary induction motors are used for variable frequency speed regulation, the cooling effect deteriorates at low speeds, and the high temperature caused by harmonics cannot be effectively dissipated, accelerating motor damage.

Key Harmonic Suppression Measures (Tailored to B2B Customer Needs)

For VFD application scenarios, the following methods can reduce the impact of harmonics on motors and improve system stability (suitable for integration into SEO content as product solutions):

- Select Inverter-Duty Motors: These motors feature high-frequency resistance, low loss, and strong insulation, adapting to the harmonic content output by VFDs.

- Equip Harmonic Mitigation Equipment: Install devices such as input reactors, output reactors, and Active Power Filters (APF) to suppress harmonics on both the grid and motor sides.

- Optimize VFD Parameters: Reduce harmonic generation by adjusting the carrier frequency and adopting vector control mode; avoid long-term operation of motors under low-speed and high-load conditions.

- Regular Maintenance and Testing: Monitor motor parameters such as temperature, vibration, and insulation resistance to promptly detect abnormalities caused by harmonics and extend equipment life.