Mechanical Characteristics of Asynchronous Motors After Frequency Conversion Speed Regulation

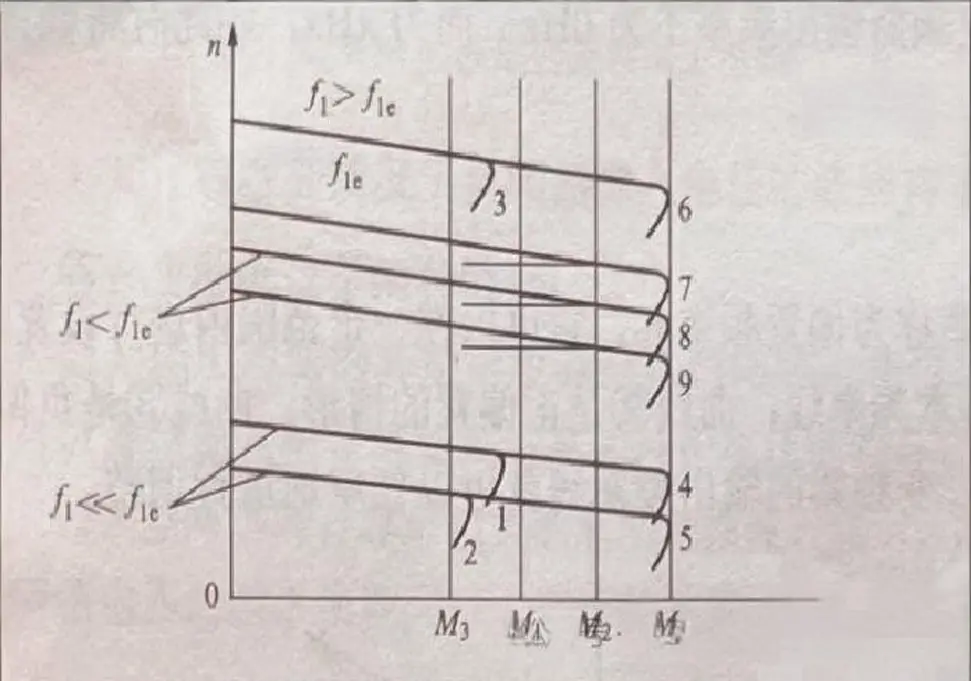

The principle of frequency conversion speed regulation is based on the formula n = 60f₁*(1-s)/p, which means that changing the stator supply frequency f₁ can alter the synchronous speed n of the motor. To maintain the motor’s maximum torque Mₘ constant during speed regulation, the stator supply voltage must be adjusted accordingly to preserve constant magnetic flux. Based on the different proportional relationships between stator voltage U₁ and stator supply frequency f₁, there are various frequency conversion speed regulation methods. Figure 1 illustrates the mechanical characteristics of asynchronous motors during frequency conversion speed regulation.

(1) Proportional control method maintaining U₁/f₁ = constant: With this method, as long as U₁ and f₁ change proportionally, constant magnetic flux can be maintained, enabling frequency conversion speed regulation. However, at low frequencies, since stator impedance cannot be ignored relative to stator leakage reactance, the maximum torque Mₘ decreases as frequency decreases, and starting torque also diminishes. Curves 4 and 5 in Figure 1 represent ideal curves at low frequencies, while curves 1 and 2 show actual performance.

(2) Constant magnetic flux control method maintaining maximum torque Mₘ constant: In this approach, to keep Mₘ unchanged, U₁ needs to be appropriately increased as f₁ decreases.

(3) Control method maintaining constant power: When f₁ > f₁ₑ (stator power frequency), maintaining U₁/f₁ = constant would inevitably cause U₁ to exceed the stator rated voltage U₁ₑ, which is not permitted. Therefore, when f₁ > f₁ₑ, the stator voltage no longer increases but remains at U₁ = U₁ₑ, and can be approximately considered as constant power speed regulation. Curve 6 in Figure 1 is the ideal curve when f₁ > f₁ₑ, while curve 3 represents actual performance.

When operating below the rated frequency f₁ₑ, the “parallel” sections of mechanical characteristic curves 7, 8, and 9 in Figure 1 offer a wide speed regulation range and can accommodate loads of different magnitudes.

When the adjusted frequency is too low, as shown in Figure 1 where f₁ < rated frequency, the actual capability diminishes, only able to satisfy small load torques such as M₃, but unable to meet slightly larger load torques like M₁ and M₂. If process equipment requires low-speed or even ultra-low-speed operation, due to excessive load that the motor cannot handle, the torque boost function of the frequency converter needs to be configured to meet the load requirements of the production process.

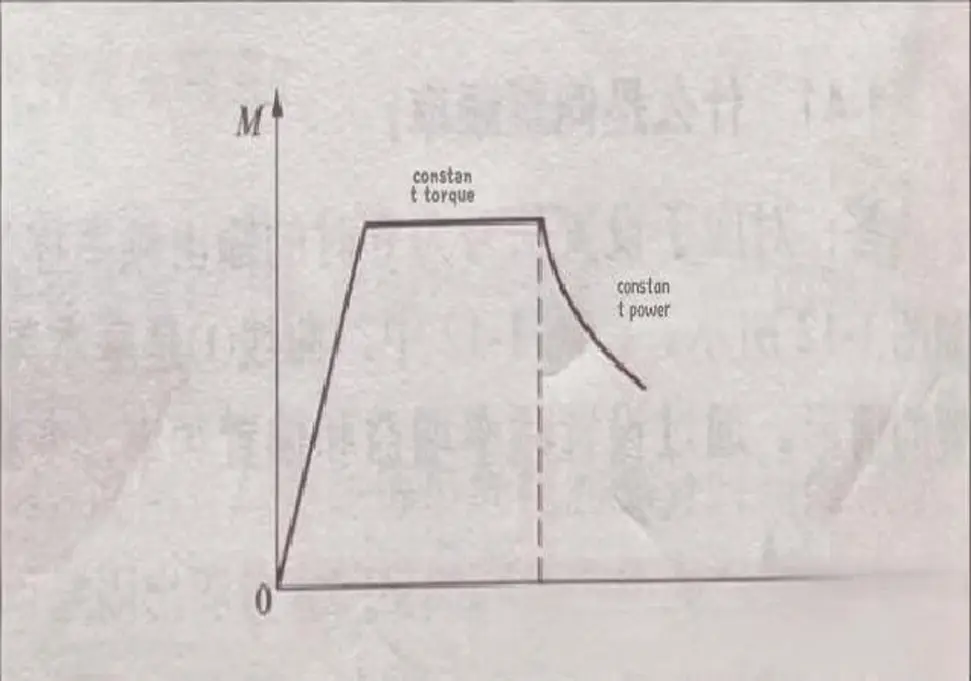

When the adjusted frequency f₁ exceeds f₁ₑ, the motor’s actual mechanical characteristics deteriorate, and load capacity decreases, as shown in curve segment 3 of curve 6 in Figure 1. At this point, the frequency converter transitions from a constant torque operating state to a constant power operating state, as illustrated in Figure 2.

Figure 1: Mechanical characteristics of asynchronous motors during frequency conversion speed regulation

Figure 2: Mechanical characteristics during constant torque and constant power speed regulation

At this stage, as frequency (speed) increases, torque M gradually decreases. However, in practical applications, adjusting speed above the rated frequency is rare and sometimes not allowed.

The frequency converter outputs the same frequency, but due to variations in load torque, there is a deviation in the motor’s actual speed. As shown in Figure 1, there is a speed deviation ⊿n between M₂ and M₁/M₃, and the greater the load change, the larger ⊿n becomes. When an absolute one-to-one correspondence between frequency and output speed is required, the motor should be replaced with a synchronous motor. The actual speed of a synchronous motor is n = 60f/p, eliminating the need for speed feedback control. Precise speed control can be achieved simply by accurately controlling the power supply frequency.