Compliant Inverter Installation: Must-Follow Precautions for Electrical Safety

Installing an inverter requires balancing electrical safety, equipment performance, and long-term stability. Strict attention must be paid to four core dimensions: environment selection, electrical connection, mechanical installation, and safety protection. Below are detailed precautions, sorted by operation process and importance:

I. Preparations: Environment Selection and Inspection

The operating environment of an inverter directly affects its service life and failure rate. Before installation, confirm that the environment meets the equipment’s requirements:

-

Temperature Control

- The ambient temperature should be maintained between -10°C and 40°C (some industrial-grade inverters can operate in an extended range of -20°C to 50°C, subject to the product manual). Avoid direct sunlight or placement near heat sources (such as boilers, motors, and heaters).

- If the temperature exceeds 40°C, the inverter’s service life may decrease by approximately 10% for each 1°C increase. Additional cooling measures—such as cooling fans, air conditioners, or heat dissipation ducts—are necessary, especially for high-power inverters (11kW and above).

-

Humidity and Dust Prevention

- The relative humidity should be controlled between 40% and 90% (no condensation). Avoid installing the inverter in humid environments (e.g., basements, areas near bathrooms) to prevent short circuits on the circuit board. In humid regions, dehumidifiers or anti-condensation heaters must be installed.

- Keep the inverter away from dust, oil mist, and corrosive gases (e.g., acid-base gases in chemical workshops). If the environment is dusty, select an inverter with a dust cover or install it in a closed control cabinet. The cabinet must have ventilation openings, and the filter screen should be cleaned regularly.

-

Vibration and Space Requirements

- The vibration acceleration at the installation location should not exceed 5.9m/s² (0.6g). Avoid rigidly connecting the inverter directly to vibration sources (e.g., pumps, fans). If necessary, install vibration dampers (such as rubber vibration isolators).

- Sufficient heat dissipation space must be reserved around the inverter: ≥10cm on the left and right sides, and ≥15cm above and below (≥20cm for high-power models). Ensure natural air convection, and do not stack debris on top of the inverter.

II. Electrical Connection: Key to Safety and Compatibility

Electrical connection is the core of the installation process. The principle of “operating with power off” must be strictly followed. Additionally, main circuits (power circuits) and control circuits (signal circuits) should be separated to avoid interference and short circuits:

1. Main Circuit Connection (Input L1/L2/L3, Output U/V/W, Grounding PE)

-

Input Side (Power Supply → Inverter)

- Install a circuit breaker (air switch) and an AC contactor (optional, for emergency power cutoff) that match the inverter’s rated current. Do not use the inverter to directly control the power supply’s on/off status, as this may damage internal modules.

- If the grid voltage fluctuates significantly or has high harmonics (e.g., when large motors start in a factory), connect a surge protector (SPD) or reactor in series on the input side. This reduces the impact of grid interference on the inverter.

- Strictly avoid connecting the input power supply to the inverter’s output terminals (U/V/W)—this will directly burn the internal IGBT module, causing an irreversible fault.

-

Output Side (Inverter → Motor)

- The cable length must meet requirements: ≤50m for ordinary motors and ≤30m for servo motors with encoders. If the length exceeds 50m, use shielded cables and install an “output reactor” to prevent excessive leakage current (caused by the cable’s distributed capacitance) from triggering the inverter’s overcurrent protection.

- Do not connect capacitors or surge absorbers in parallel on the output side—this will distort the inverter’s output current and lead to overheating.

- If controlling multiple motors, ensure the sum of each motor’s rated current is ≤ the inverter’s rated current. Additionally, equip each motor with an independent thermal relay to prevent the inverter from failing to provide accurate protection when a single motor is overloaded.

-

Grounding Connection (PE)

- Adopt independent grounding with a grounding resistance ≤4Ω (≤2Ω for high-power inverters). Do not share a grounding electrode with power equipment (e.g., motors, water pumps), as this may cause grounding loops that interfere with the inverter’s signals.

- The cross-sectional area of the grounding wire must be appropriate: ≥2.5mm² when the inverter’s rated current is ≤10A; ≥4mm² for 10A–50A; and ≥6mm² (copper core wire) for currents above 50A. Ensure the grounding bolt is tightly fastened to prevent electric leakage due to poor contact.

2. Control Circuit Connection (Signal Terminals: Start/Stop, Speed Regulation, Feedback)

-

Separation of Signal Cables and Power Cables

- Use shielded twisted-pair cables for control signal cables (e.g., start/stop signals from PLC outputs, speed regulation signals from potentiometers, feedback signals from encoders). Keep these cables at a distance of ≥10cm from main circuit cables (power cables). When crossing, ensure they cross vertically to avoid strong electromagnetic interference from power cables—this interference can cause signal distortion and trigger incorrect inverter operation.

- Ground the shield layer only at one end (ground it on the inverter side and leave the other end floating). Do not ground both ends, as this may form grounding loops and introduce interference.

-

Power Isolation

- Isolate the control circuit’s power supply (e.g., 24V DC power supply) from the main circuit’s power supply. It is recommended to use a switching power supply for independent power supply to avoid the impact of main circuit voltage fluctuations on the stability of control signals.

- Do not directly connect a 220V AC power supply to the inverter’s low-voltage control terminals (e.g., COM, DI1 terminals)—this will burn the internal optocoupler.

III. Mechanical Installation: Ensuring Stability and Heat Dissipation

-

Selecting the Installation Method

- Wall-mounted installation: Suitable for low-power inverters (≤30kW). The installation surface must be a solid wall (e.g., a concrete wall) with a load-bearing capacity ≥5 times the inverter’s weight. Do not install the inverter on lightweight partition walls or wooden boards, as this may cause loosening due to vibration.

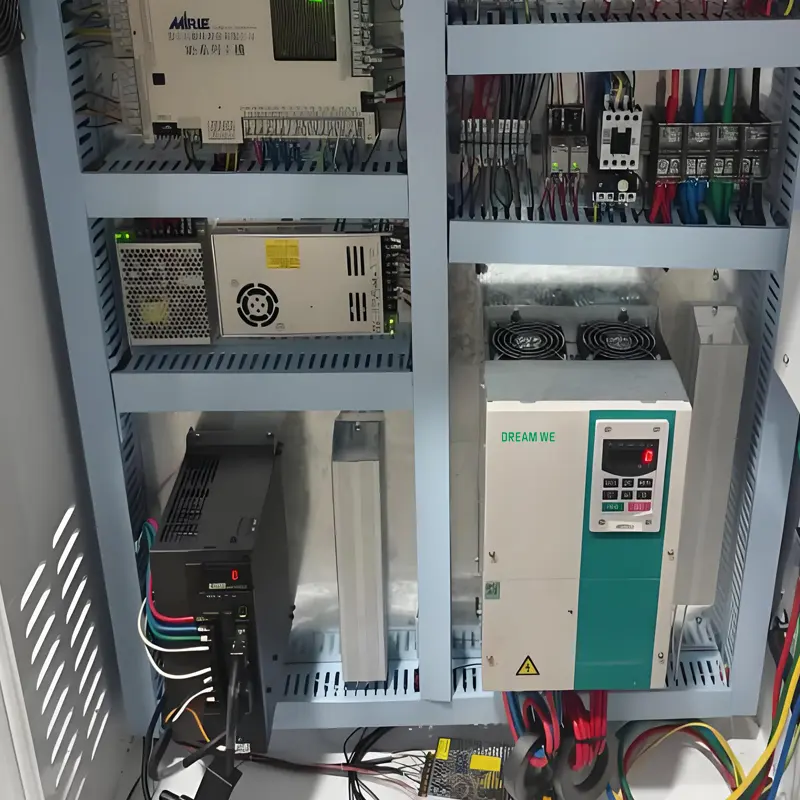

- Cabinet installation (inside a control cabinet): Reserve air inlets (equipped with dust filters) at the bottom of the control cabinet and install exhaust fans at the top. The fans’ air volume must be ≥1.2 times the inverter’s heat dissipation requirement to ensure air flows from bottom to top. If multiple inverters are installed side by side, install partitions between adjacent inverters to prevent mutual interference from hot air.

-

Wiring Specifications

- Route main circuit cables and control circuit cables in separate slots (use metal wire troughs to separate them inside the control cabinet). This avoids messy cables (which complicate later maintenance) and short circuits caused by cable extrusion or damage.

- Clearly label both ends of the cables (e.g., “Input L1”, “Output U – Motor 1”, “Control DI1 – Start/Stop”) to facilitate troubleshooting.

IV. Safety Protection and Post-Installation Inspection

-

Power-Off Operation and Insulation Testing

- After completing all wiring, disconnect the main power supply first and use a multimeter to perform the following tests:

- The insulation resistance between the input side (L1/L2/L3) and the ground should be ≥5MΩ (measured with a 500V megohmmeter);

- The insulation resistance between the output side (U/V/W) and the ground should be ≥1MΩ;

- Ensure there is no short circuit between the control circuit terminals (e.g., 24V, COM) and the ground to prevent damage to the control board when power is applied.

- After completing all wiring, disconnect the main power supply first and use a multimeter to perform the following tests:

-

Parameter Setting Before Power-On

- Before powering on the inverter for the first time, set its core parameters via the inverter panel or software (e.g., PLC, upper computer):

- The motor’s rated voltage, rated current, and rated speed (must match the motor’s nameplate). If they do not match, the inverter cannot control the motor accurately, which may easily cause overload or overcurrent;

- Acceleration/deceleration time (adjust based on load characteristics. For example, a conveyor belt that starts with a load requires an extended acceleration time to avoid excessive starting current);

- Protection functions (e.g., set the overcurrent protection value to 1.2 times the motor’s rated current and the overvoltage protection value to 1.1 times the grid voltage).

- Before powering on the inverter for the first time, set its core parameters via the inverter panel or software (e.g., PLC, upper computer):

-

Test Run and Monitoring

- During the first power-on, conduct a no-load test run first: disconnect the motor output and only power on the inverter. Check if the panel displays any fault codes (e.g., E001 for overcurrent, E002 for overvoltage). If there are no faults, connect the motor.

- During the load test run, monitor the inverter’s output current and temperature (displayed on the panel or measured with an infrared thermometer). A shell temperature ≤60°C is normal. If there is excessive current fluctuation or high temperature, stop the machine and check the wiring and parameters.

V. Avoiding Common Misconceptions

- Assuming “inverters do not need grounding”: Without proper grounding, the inverter’s shell will become electrified, posing an electric shock risk. It may also introduce interference, leading to incorrect inverter alarms.

- Randomly extending output cables: Extending cables beyond 50m without adding a reactor will cause excessive leakage current, triggering “overcurrent protection” and even burning the module.

- Operating at full load immediately after power-on: Gradually increase the frequency from a low level (e.g., 5Hz) to the rated frequency. This allows the motor and inverter to adapt and avoids instantaneous inrush current.

In conclusion, inverter installation should follow this sequence: “first check the environment, then inspect the wiring, next set the parameters, and finally conduct the test run”. Each step must align with the equipment manual (details may vary among different inverter brands) to ensure safety and performance. This approach maximizes the equipment’s service life and reduces faults.