Core Hazards of VFD Harmonics and Impact Scenarios

I. Hazards to Power Systems

-

Increased Grid Losses and Reduced Power Supply Efficiency

Harmonic currents induce additional active power losses (including increased copper loss and iron loss) in power transmission lines, transformers, and other electrical equipment, which lowers grid transmission efficiency. Power companies must invest more to offset these losses, costs that may ultimately be passed on to enterprise users through electricity pricing. For regions with underdeveloped power grid infrastructure—such as Africa, Southeast Asia, and South America—this loss issue is more pronounced and can even worsen power shortages.

-

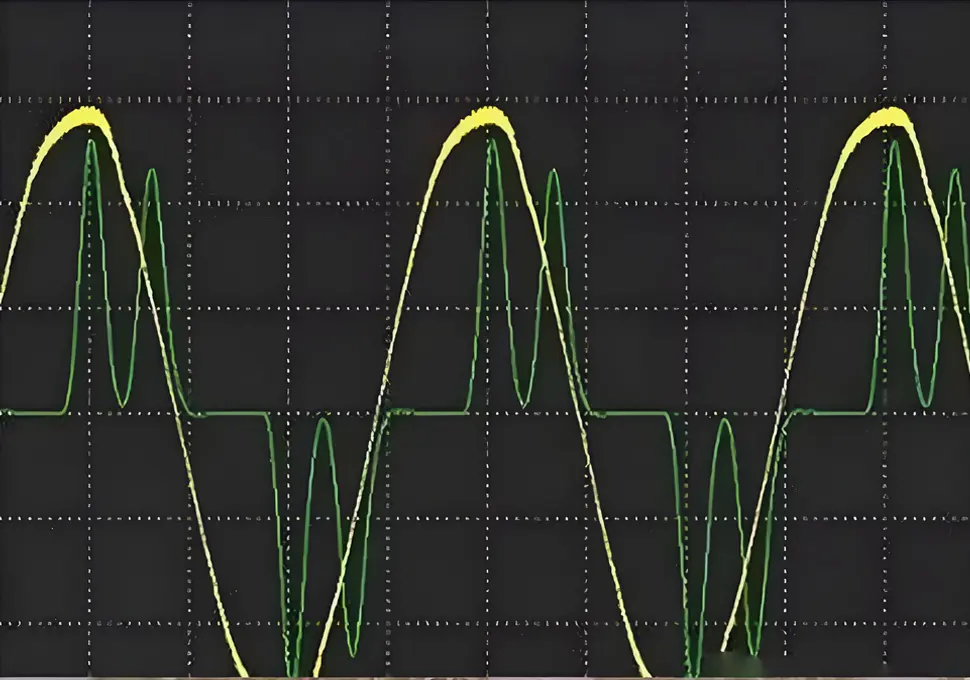

Compromised Grid Voltage Quality and Voltage Distortion

Harmonic voltages superimpose on fundamental voltages, causing voltage waveform distortion, fluctuations, and flicker. This undermines the stability of the entire power grid and may trigger malfunctions in sensitive equipment (e.g., precision instruments, PLC control systems), particularly impacting manufacturing production lines that rely on stable power supply.

-

Interference with Relay Protection and Automatic Control Devices

Harmonics can distort the operational logic of relay protection devices, fuses, and other equipment, leading to false tripping or failure to activate. In severe cases, this can escalate power grid faults and cause large-scale blackouts. For example, in factory power distribution systems, harmonics may trigger conflicts between VFDs and the protection devices of other equipment, disrupting production continuity.

-

Malfunctions in Reactive Power Compensation Equipment

Harmonic currents cause overcurrent and overheating in capacitor compensation devices, accelerating capacitor aging or even causing explosions. Additionally, they reduce the effectiveness of reactive power compensation, further deteriorating the grid’s power factor. For enterprises seeking to lower electricity costs via reactive power compensation, harmonics directly increase their energy expenses.

II. Hazards to Electrical Equipment

-

Accelerated Motor Damage and Shortened Equipment Lifespan

Harmonics generate additional losses inside motors, resulting in increased heat generation and accelerated insulation aging. They also produce negative sequence torque, which reduces motor efficiency and output power while raising equipment failure rates. For instance, water pump and fan motors driven by VFDs may suffer from bearing wear, winding burnout, and other issues when operating in a harmonic environment long-term—increasing enterprise maintenance and replacement costs.

-

Interference with Precision Electronic Equipment Operation

Through conduction, radiation, and other pathways, harmonics disrupt precision electronic equipment such as PLCs, sensors, and monitoring systems. This causes data transmission errors and control signal distortion, potentially leading to production line shutdowns or product quality defects. In industries requiring high precision (e.g., automotive manufacturing, electronic component processing), such interference can result in significant economic losses.

-

Degraded Performance of Transformers, Reactors, and Other Equipment

Harmonics cause transformer core saturation, increasing iron loss and copper loss. This leads to transformer overheating, elevated noise levels, and shortened service life. Simultaneously, harmonic currents may induce magnetic saturation in reactors, reducing their filtering and current-limiting capabilities and further amplifying harmonic hazards.

-

Damage to Lighting Equipment

Harmonic voltages cause flickering and shortened lifespans in lighting equipment (e.g., fluorescent lamps, LED lights) and may even burn them out in severe cases. For enterprise offices and production workshops, lighting failures hinder work efficiency and raise maintenance costs.

III. Indirect Hazards to Enterprise Operations

-

Higher Electricity Costs

Beyond increased electricity fees due to grid losses, power companies in some regions levy additional fines or surcharges on enterprises with excessive harmonics. Furthermore, downtime losses and maintenance costs from equipment failures further drive up operational expenses.

-

Impaired Product Quality and Production Efficiency

For production processes relying on VFDs for precise speed regulation (e.g., assembly lines, CNC machine tools), harmonic-induced equipment failures or reduced control accuracy lower product qualification rates and delay production schedules. This damages enterprise reputation and market competitiveness.

-

Elevated Safety Risks

Harmonic-related issues—such as equipment overheating, capacitor explosions, and wire aging—may trigger safety accidents (e.g., fires, electric shocks), endangering employee safety and enterprise property.

IV. Special Considerations for Developing Country Markets

Core Directions for Harmonic Mitigation

- Select low-harmonic VFDs (e.g., high-performance models adopting PWM technology);

- Install harmonic mitigation equipment such as passive filters and active power filters (APF);

- Optimize power distribution system design and properly configure transformers, reactors, and other equipment;

- Regularly conduct grid harmonic detection and analysis, adjusting mitigation solutions promptly.