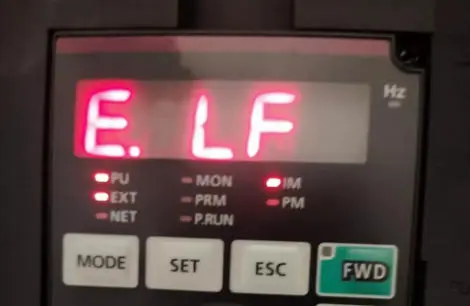

To prevent the variable frequency drive from reporting an E.LF (output phase loss or load fault) fault, measures should be taken from multiple aspects, including equipment installation, parameter settings, and daily maintenance, to reduce the likelihood of the fault being triggered. The following are specific preventive measures:

1. Optimize power supply and wiring to avoid electrical connection issues

– Ensure stable power supply:

Large fluctuations in the VFD’s input voltage (e.g., exceeding ±10% of the rated value) may cause abnormal current. Install a voltage stabilizer or isolation transformer at the power supply end, especially in industrial environments with unstable power grids.

– Standardize wiring and tightening:

– The motor cables must be securely connected to the VFD output terminals (U, V, W). Regularly inspect the terminal block screws for loosening (recommended every 3 months) to prevent phase loss due to poor contact.

– Motor cables must use copper-core wires that meet specifications, avoiding cables that are too thin (causing excessive line loss) or too long (exceeding the VFD’s maximum allowed cable length, generally recommended ≤50 meters; for longer distances, use thicker cables or reduce the carrier frequency).

– Distinguish between input (L1, L2, L3) and output (U, V, W) terminals; reverse connections are strictly prohibited to prevent damage to internal components.

2. Properly configure parameters to match load characteristics

– Set the correct motor parameters:

Based on the motor nameplate (rated power, voltage, current, speed), accurately input the parameters into the VFD (such as motor rated current, no-load current, pole number, etc.) to ensure that the VFD’s motor protection logic matches the actual load.

– Adjust protection thresholds and response times:

– Appropriately relax the thresholds for overcurrent and overload protection (but not exceeding 1.2 times the motor’s rated value) to avoid false alarms caused by momentary load fluctuations (such as startup surges).

– Extend the response time for low voltage protection (e.g., from the default 0.1 seconds to 0.3 seconds) to reduce false triggers caused by short-term grid fluctuations.

3. Regularly maintain motors and cables to reduce load-side faults

– Motor condition inspection:

– Regularly (every 6 months), use a megohmmeter to test the motor winding insulation resistance (should be ≥5MΩ) to prevent winding moisture, short circuits, or ground faults.

– Inspect motor bearings for wear or binding, and promptly apply lubricating grease to prevent abnormal current due to excessive mechanical resistance.

– Cable and joint maintenance:

– Avoid squeezing, dragging, or exposing cables to high temperatures. Regularly inspect the outer sheath for damage and the internal copper core for oxidation (oxidation increases contact resistance).

– For motors that are frequently moved (such as conveyors or pumps), prioritize the use of flexible cables and install waterproof and dustproof sleeves at the connectors.

4. Enhance maintenance of the variable frequency drive itself to prevent internal faults

– Cleaning and heat dissipation management:

– Regularly (every 3-6 months) clean dust from the interior of the VFD, especially the cooling fans and heat sinks, to ensure proper ventilation (ambient temperature must be ≤40°C; install additional cooling fans or air conditioning if exceeded).

– Check fans for abnormal noise or stoppage, and promptly replace damaged fans (typical lifespan is 2-3 years).

– Internal Component Inspection:

– During shutdown, inspect internal capacitors for swelling or leakage, and IGBT modules for overheating or discoloration. Replace any abnormal components promptly (the capacitor lifespan is approximately 5-8 years, significantly influenced by ambient temperature).

– For VFDs in use for over 5 years, it is recommended to have professional personnel annually inspect the accuracy of current detection circuits, Hall sensors, and other protective components.

5. Improve the operating environment and reduce external interference

– Avoid electromagnetic interference:

The output cables and signal lines (such as sensor lines and control lines) of the variable frequency drive should be laid separately (with a spacing of ≥30 cm), or the signal lines should be shielded with metal tubes to prevent high-frequency harmonic interference from the high-frequency drive from causing incorrect current detection.

– **Moisture, dust, and vibration protection**:

The control cabinet housing the variable frequency drive must be well-sealed to prevent dust and moisture ingress. Near equipment with significant vibration (such as punch presses or crushers), the variable frequency drive must be fitted with vibration-damping pads to minimize the impact of mechanical vibration on internal wiring and components.

6. Establish a fault logging and early warning mechanism

– Record the trigger time and operating conditions (such as load size, ambient temperature, and whether the equipment is in the startup or shutdown phase) for each E.LF fault, analyze whether there are any patterns (such as frequent occurrences during specific periods or under specific load conditions), and conduct targeted investigations to identify the causes.

– For critical equipment, operational data (current, voltage, temperature) can be uploaded to the monitoring system via the VFD’s communication interface (e.g., RS485, PROFINET), and warning thresholds for current imbalance and voltage fluctuations can be set to enable proactive intervention.

By implementing the above measures, the probability of E.LF faults can be significantly reduced, while extending the service life of the VFD and motor and ensuring stable equipment operation. If faults occur frequently and cannot be identified, it is recommended to contact the VFD manufacturer or professional maintenance personnel for a thorough inspection.