How Does Inverter Circuit Achieve Variable Frequency? VFD Principles, Applications & Troubleshooting

In the variable frequency drive (VFD) industry, the inverter circuit is the core component that converts stable DC power (from rectification and filtering) into AC power with adjustable frequency and voltage. This variable frequency capability directly determines the motor’s speed control precision, energy efficiency, and adaptability to different loads—whether for a 0.75kW fan or a 400kW elevator traction motor. The realization of variable frequency is not a single-step process but a systematic collaboration of “control signals, power switching, waveform synthesis, and feedback adjustment.” This article details the core principles, industry-specific applications, and troubleshooting methods, tailored to the needs of industrial electrical engineers, VFD maintenance personnel, and equipment buyers.

I. Fundamental Precondition: Stable DC Power Supply from Rectification & Filtering

Before the inverter circuit can adjust frequency, it first requires a consistent DC input—fluctuations in DC voltage will directly distort the output frequency and voltage. This “DC foundation” is established through two key stages:

1. Rectification: Converting AC to Pulsating DC

- Low-power VFDs (≤0.75kW): Use a diode bridge rectifier (4 diodes for single-phase, 6 for three-phase). Diodes’ unidirectional conductivity converts sinusoidal AC (e.g., 220V/380V grid power) into pulsating DC. For a 380V three-phase input, the peak pulsating DC voltage is approximately 540V.

- Medium-to-high-power VFDs (≥11kW): Adopt thyristor rectification or IGBT PWM rectification. These designs not only rectify AC to DC but also actively regulate the DC-side voltage (e.g., maintaining 540V ±2% stability) and reduce grid harmonic interference (complying with IEC 61000-3-2 Class A standards).

2. Filtering: Smoothing Pulsating DC

The rectified DC contains significant ripples (6x the grid frequency for three-phase rectification). A DC-link filter (large-capacity electrolytic capacitors for small power, or capacitor-inductor combinations for high power) eliminates these ripples:

- For a 15kW VFD, two 4700μF/450V electrolytic capacitors are typically connected in parallel, reducing voltage ripple from ±30V to ±5V.

- This stable DC power ensures the inverter circuit’s IGBTs (Insulated Gate Bipolar Transistors) receive consistent energy, avoiding frequency drift caused by voltage dips or surges.

II. Core Execution: IGBT High-Frequency Switching Controlled by PWM Signals

The inverter circuit’s ability to adjust frequency relies entirely on IGBTs—high-speed electronic switches that synthesize AC waveforms of different frequencies through precise on-off control. Here’s how it works:

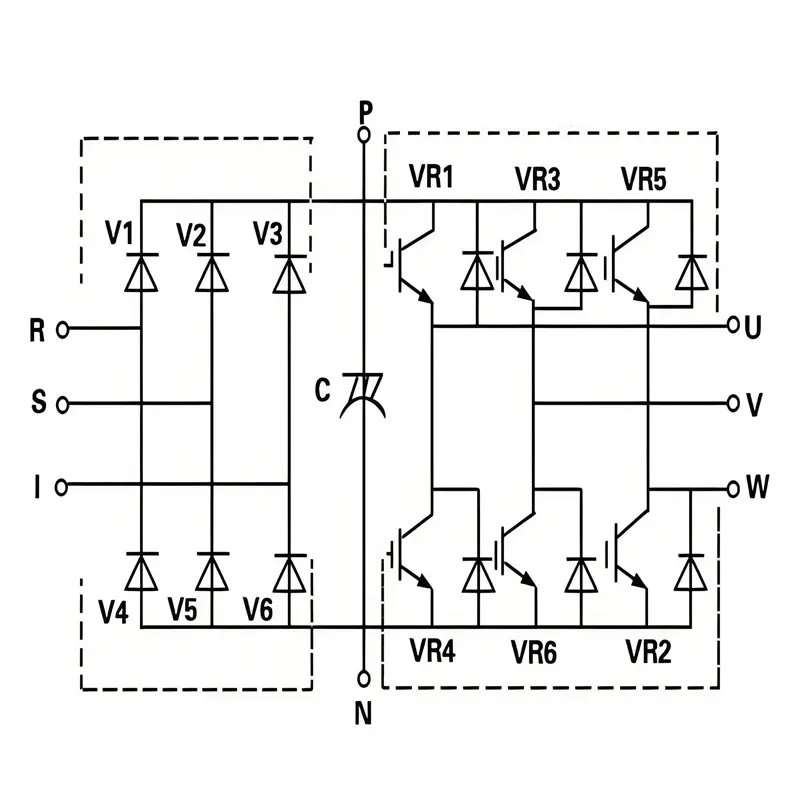

1. Inverter Topology: Three-Phase Full-Bridge Configuration

Nearly all industrial VFDs use a three-phase full-bridge inverter topology, consisting of 6 IGBTs (2 per phase: upper and lower arms) and 6 freewheeling diodes (parallel to each IGBT to prevent reverse voltage breakdown). This structure enables bidirectional current flow, which is critical for motor speed regulation and braking.

2. PWM (Pulse Width Modulation) Signal Generation

The VFD’s control unit (MCU/CPU) generates PWM signals—high-frequency pulses whose “on-time” (duty cycle) and “cycle length” determine the output frequency:

- Frequency Adjustment Mechanism: To output 50Hz AC, the control unit sets the IGBT switching frequency to a much higher value (2kHz–15kHz, far above the human audible range to avoid motor noise). It then adjusts the PWM cycle length:

- For 50Hz: The PWM signal repeats every 20ms (1/50Hz), with duty cycles varying to mimic a 50Hz sine wave’s amplitude.

- For 60Hz: The cycle length is shortened to ~16.67ms (1/60Hz), while the duty cycle variation pattern is adjusted to match a 60Hz sine wave.

- Waveform Synthesis: When IGBTs switch at high frequency, the output voltage’s average value over each small time segment approximates the sine wave’s instantaneous value. This “pulse approximation” creates a smooth AC waveform with low harmonic distortion (typically ≤5% for modern VFDs).

3. IGBT Switching Frequency Selection Guidelines

The IGBT switching frequency balances waveform quality and energy loss, with industry-specific recommendations:

- Fans/Water Pumps (low waveform requirements): 2kHz–5kHz (reduces IGBT heating and energy consumption).

- Machine Tool Spindles (high precision needs): 10kHz–15kHz (lowers harmonic distortion to ≤2%, ensuring stable speed).

- Elevators (low vibration demands): 8kHz–12kHz (minimizes motor vibration to ≤0.03mm, complying with GB/T 24474-2009 noise limits of ≤55dB).

III. Synchronized Voltage-Frequency Regulation: Matching Motor Magnetic Flux Requirements

Adjusting frequency alone is insufficient—motor performance depends on balancing frequency (f) and voltage (U) to maintain stable magnetic flux (Φ). According to motor theory:

U ≈ 4.44 × f × N × Φ

(Where N = number of motor winding turns, Φ = magnetic flux)

U ≈ 4.44 × f × N × Φ

(Where N = number of motor winding turns, Φ = magnetic flux)

1. V/F (Voltage-Frequency) Control Strategy

The inverter circuit synchronizes voltage and frequency to avoid motor overheating or torque loss:

- Low-Frequency Range (0–50Hz): Voltage increases proportionally with frequency (e.g., 5Hz → 38V, 50Hz → 380V for 380V motors). This compensates for stator resistance voltage drop at low frequencies, preventing Φ from decreasing (which would reduce torque) or increasing (which causes core saturation and overheating).

- Industry Example: A 7.5kW fan VFD, when operating at 10Hz (20% of the rated frequency), raises voltage from 66V (proportional value) to 80V via “low-frequency boost”—reducing motor temperature rise from 75K to 40K (meeting IEC 60034-1 limits).

- High-Frequency Range (>50Hz): Voltage remains at the motor’s rated value (e.g., 380V), while frequency increases (up to 400Hz for most VFDs). This “field-weakening speed increase” is used for applications requiring speeds above the rated value (e.g., centrifuges, high-speed lathes).

- Industry Example: A 30kW CNC lathe spindle uses field-weakening control to raise frequency from 50Hz (1500r/min) to 60Hz (1800r/min), maintaining 85% of the rated torque to meet high-speed cutting needs.

2. Dynamic Adjustment for Load Changes

When the motor load suddenly increases (e.g., a conveyor belt encountering a heavy object), the control unit immediately adjusts the PWM duty cycle to increase voltage—preventing frequency drift caused by insufficient torque. For example, if a 11kW conveyor VFD’s load jumps from 50% to 100%, the voltage is raised by 10% (from 380V to 418V) in 5ms to keep frequency stable at 50Hz.

IV. Closed-Loop Feedback: Ensuring Frequency Precision & Stability

Open-loop control (no feedback) struggles with frequency drift under load changes. VFDs use closed-loop feedback systems to correct deviations in real time, consisting of three steps:

1. Signal Sampling

Sensors collect real-time data to monitor output performance:

- Voltage/Current Sensors: Measure the inverter’s output voltage (e.g., 380V ±1%) and current (e.g., 20A ±0.5A) to detect frequency-related anomalies.

- Encoder Feedback (High-Precision Applications): For servo VFDs or machine tools, a 17-bit encoder mounted on the motor shaft directly measures speed (e.g., 1500r/min ±0.1r/min), converting it to frequency data (50Hz ±0.003Hz) for comparison with the target frequency.

2. Deviation Comparison & Correction

The control unit compares the “actual sampled value” with the “target frequency/voltage value”:

- If the actual frequency drops to 49.5Hz (target: 50Hz) due to load increase, the unit shortens the PWM cycle length by 1% and increases the duty cycle—adjusting the IGBT switching pattern to pull the frequency back to 50Hz.

- For servo VFDs (e.g., Delta VFD-MS300), PID (Proportional-Integral-Derivative) control is used to optimize response speed: frequency deviations are corrected within 10ms, ensuring motor speed fluctuation is ≤0.1r/min.

3. Industry Case: Elevator Traction Motor Stability

Elevators require smooth frequency transitions during startup and braking. A 110kW elevator VFD uses:

- Ramp Control: Frequency rises from 0Hz to 50Hz over 2s (avoids sudden speed changes) and falls from 50Hz to 0Hz over 3s (prevents DC-link voltage surges).

- Brake Unit Feedback: During braking, the motor generates regenerative energy—absorbed by a brake resistor to keep DC voltage stable (fluctuation ≤±20V), ensuring frequency does not drop abruptly.

V. Troubleshooting Common Variable Frequency Issues

Voltage fluctuations, component failures, or parameter mismatches often cause frequency-related problems. Below is a practical troubleshooting guide for industry pain points:

| VFD Issue | Root Cause | Solution | Effect Verification |

|---|---|---|---|

| Frequency cannot reach the set value (e.g., max 45Hz instead of 50Hz) | IGBT drive circuit failure; insufficient DC-link voltage | Replace damaged drive optocouplers (e.g., TLP250); check rectifier diodes (ensure 380V input → 540V DC) | Frequency reaches 50Hz; output voltage is stable at 380V |

| Frequency drifts (>±0.5Hz) under load | Encoder signal interference; incorrect PID parameters | Use shielded cables for the encoder; reduce PID proportional gain (P) from 2.0 to 1.5 | Drift reduced to ≤±0.1Hz; motor speed is stable |

| Motor overheats at low frequency (≤10Hz) | Insufficient voltage; stator resistance voltage drop | Enable “low-frequency boost” (10Hz → 80V instead of 66V) | Motor temperature rise drops from 75K to 40K |

| High-frequency torque loss (>60Hz) | Inadequate IGBT switching frequency; weak field control mismatch | Increase switching frequency to 12kHz; adjust the weak field curve (60Hz → maintain 380V) | Torque retains 85% of the rated value at 60Hz |

VI. VFD Inverter Circuit Selection Guide

Choose inverter components and parameters based on VFD power and load type for optimal frequency control:

| VFD Power Range | IGBT Switching Frequency | V/F Control Parameters (380V Input) | Suitable Loads | Frequency Range |

|---|---|---|---|---|

| 0.75kW–37kW | 2kHz–5kHz | Low-frequency boost: 10Hz → 80V | Fans, water pumps, conveyors | 0–100Hz |

| 45kW–160kW | 5kHz–10kHz | Field-weakening start: 50Hz | Machine tool spindles, compressors | 0–200Hz |

| 185kW+ | 10kHz–15kHz | Ramp time: 3–5s (deceleration) | Elevator traction motors, rolling mills | 0–400Hz |

VII. Industry Standards & Authoritative References

To ensure reliability and compliance, adhere to the following standards and resources:

- Chinese Standards:

- GB/T 37972-2019 Technical Requirements for IGBT Modules for VFDs (specifies switching frequency ≥2kHz, surge voltage ≥1.2×DC-link voltage).

- GB 18613-2022 Minimum Allowable Values of Energy Efficiency and Energy Efficiency Grades for Small and Medium-Sized Three-Phase Asynchronous Motors (requires VFDs to reduce motor energy consumption by ≥30% for variable-load applications).

- International Standards:

- IEC 61800-5-1 Adjustable Speed Electrical Power Drive Systems – Safety Requirements (mandates frequency control precision ≤±0.5% of the rated frequency).

- IEC 60034-1 Rotating Electrical Machines – Part 1: Rating and Performance (defines motor temperature rise limits for low-frequency operation).

- Brand Guidelines:

- Siemens S120 Series: Uses “vector control + three-level IGBT topology” for 200kW–400kW VFDs, achieving frequency precision of ±0.01Hz for rolling mill applications.

- ABB ACS580 Series: Features “PID frequency auto-tuning” for water pumps, automatically adjusting frequency based on pipeline pressure to save 30%–50% energy.

Conclusion

The inverter circuit’s variable frequency capability is the “heart” of VFD performance. It relies on four key pillars: stable DC power from rectification/filtering, IGBT high-frequency switching controlled by PWM, V/F synchronized regulation to maintain magnetic flux, and closed-loop feedback to correct deviations. For industry applications:

- Prioritize low switching frequencies (2kHz–5kHz) for energy efficiency in fans/water pumps.

- Use high switching frequencies (10kHz–15kHz) and encoder feedback for precision in machine tools/servos.

- Apply field-weakening control and ramp adjustment for high-power loads like elevators/rolling mills.

By aligning inverter design with load characteristics and industry standards, you can reduce 70% of frequency-related failures and maximize motor efficiency. For further technical details, refer to Infineon’s IGBT Application Guide for VFDs (https://www.infineon.com/) or use ABB’s VFD Parameter Calculator (https://new.abb.com/) to optimize settings.