How to Determine the Required Inverter Protection Level for a Specific Environment

Step 1: Understand the Core Protection Standard – The IP Rating System (Basic Framework)

1. First Characteristic Digit (Dust Protection Level: Grades 0–6; higher grades indicate stronger protection)

| Grade | Description of Protection Capability | Core Applicable Scenarios |

|---|---|---|

| 0 | No protection | Only used in absolutely dust-free laboratory environments (rarely applied) |

| 1 | Protects against solids with a diameter of ≥ 50mm (e.g., large gravel, tools) | Dry, dust-free indoor fixed locations (e.g., small equipment in offices) |

| 2 | Protects against solids with a diameter of ≥ 12.5mm (e.g., small gravel, fingers) | Dry, low-dust indoor environments (e.g., control cabinets in workshops far from dust-generating points) |

| 3 | Protects against solids with a diameter of ≥ 2.5mm (e.g., metal chips, dust particles) | Indoor environments with mild dust (e.g., non-cutting areas in mechanical processing workshops) |

| 4 | Protects against solids with a diameter of ≥ 1.0mm (e.g., fine dust, fibers) | Indoor environments with moderate dust (e.g., areas around control rooms in flour mills and feed factories) |

| 5 | Dust-protected (dust cannot be completely blocked from entering, but the amount that enters does not affect the equipment’s normal operation) | Heavy dust environments (e.g., workshops in mines and cement plants) |

| 6 | Totally dust-tight (no dust entry) | Extreme dust environments (e.g., on-site installations in coal powder silos and ore crushing workshops) |

2. Second Characteristic Digit (Water Protection Level: Grades 0–9K; higher grades indicate stronger protection)

| Grade | Description of Protection Capability | Core Applicable Scenarios |

|---|---|---|

| 0 | No protection | Environments with absolutely no water contact (e.g., dry indoor control cabinets) |

| 1 | Protects against vertically dripping water (e.g., condensed water, slight dripping) | Indoor environments with no spraying or standing water (e.g., ordinary workshops) |

| 2 | Protects against dripping water within a 15° tilt angle (e.g., slight roof leakage, dripping when equipment is installed at an angle) | Indoor areas where slight water splashing may occur (e.g., equipment near air conditioning vents) |

| 3 | Protects against sprayed water within a 60° tilt angle (e.g., light rain, low-pressure spraying) | Outdoor environments with shelter (e.g., under eaves, outdoor control cabinets) |

| 4 | Protects against splashing water from any direction (e.g., water for floor cleaning, moderate rain) | Outdoor unshielded environments or indoor areas requiring cleaning (e.g., car washes, cleaning areas in food processing workshops) |

| 5 | Protects against water jets from any direction (e.g., high-pressure water gun spraying at a distance of ≥ 3m) | Environments requiring high-pressure cleaning (e.g., slaughterhouses, farms, cooling areas in metallurgical workshops) |

| 6 | Protects against powerful water jets (e.g., high-pressure water gun spraying at a close range of ≥ 1m) | Extreme water spraying environments (e.g., outdoor rain-exposed equipment, humid areas at docks) |

| 7 | Protects against short-term immersion (immersed in 1m-deep water for 30 minutes without water entry) | Environments prone to short-term water accumulation (e.g., underground garages, equipment in low-lying areas) |

| 8 | Protects against continuous immersion (continuously immersed in water at a specified depth without water entry; the specific depth is defined by the manufacturer) | Environments with long-term humidity or potential for submersion (e.g., near sewage treatment tanks, underwater equipment) |

| 9K | Protects against high-temperature, high-pressure water jets (80℃ high temperature, 80–100bar high-pressure water spraying) | High-temperature cleaning environments (e.g., automobile painting workshops, high-temperature sterilization workshops) |

Step 2: Analyze Environmental “Threat Factors” (Key Input)

1. Solid Contaminants: Focus on “Dust Type + Concentration”

- Ordinary dust: Examples include metal chips from mechanical processing and cement dust in the construction materials industry. Pay attention to the dust particle diameter (refer to the “solid diameter” specified in the IP dust protection level).

- Corrosive dust: Examples include acid-base dust in the chemical industry and metal dust in electroplating workshops. In addition to meeting the IP dust protection level, the inverter shell should be made of corrosion-resistant materials (e.g., 304 stainless steel).

- Fibrous impurities: Examples include cotton lint in textile workshops and pulp fibers in paper mills. These impurities easily block the inverter’s heat dissipation holes, so an IP5X or higher dust protection level is required. Priority should also be given to models with “detachable dust filters”.

2. Liquid Contaminants: Focus on “Liquid Type + Contact Method”

- Water droplets/condensed water: Common in environments such as under air conditioning vents or humid basements. An IPX1 or IPX2 rating is sufficient for such scenarios.

- Splashed water/cleaning water: Typical in settings like food processing workshops (for equipment cleaning) or car washes. An IPX4 or higher rating is required here.

- High-pressure water jets: Found in environments such as slaughterhouses (for high-pressure floor cleaning) or metallurgical workshops (for cooling water spraying). An IPX5 or IPX6 rating is needed.

- Corrosive liquids: Examples include acid-base solutions in chemical workshops and electroplating wastewater. Besides meeting an IPX4 or higher water protection level, the inverter shell should be treated with an anti-corrosion coating.

3. Ambient Temperature: Affects the Balance Between Protection Level and Heat Dissipation

- High-temperature environments (e.g., metallurgical workshops, boiler rooms, where the temperature exceeds 40℃): If an IP6X fully dust-tight rating is selected, the inverter must be equipped with a “forced air cooling” or “water cooling” heat dissipation module. Fully sealed shells tend to accumulate heat, which can trigger overload protection.

- Low-temperature environments (e.g., cold storage facilities, outdoor winter conditions, where the temperature is below -10℃): Inverters with a “low-temperature startup function” should be chosen, and the protection level is preferably IP5X (to balance dust protection and heat dissipation, and avoid low-temperature condensation).

4. Special Environments: Additional Requirements Beyond the IP Rating

- Explosive environments (e.g., gas stations, flammable and explosive areas in chemical plants): The IP rating is only a basic requirement; additional explosion-proof grades (e.g., Ex d IIB T4 Ga, which corresponds to different explosive hazard zones) are mandatory. Such inverters must pass explosion-proof certification (e.g., CNEx certification in China).

- Outdoor environments (e.g., open-air photovoltaic power stations, outdoor pump stations): In addition to an IPX5/IPX6 water resistance rating, additional measures for “sun protection” (e.g., adding a sunshade to the shell) and “condensation prevention” (e.g., installing a built-in heater) are needed. These prevent UV-induced aging and internal water condensation caused by temperature differences.

5. Installation Method: Affects the Actual Protection Effect

- Wall-mounted installation: If the inverter is installed near the ground (less than 1.5m high), it is prone to water splashing or dust accumulation. An IP54 or higher rating is required.

- Floor-mounted installation (e.g., independent control cabinets): The bottom of the cabinet is prone to water accumulation, so an IP54 rating plus a “waterproof base” installed at the bottom is necessary.

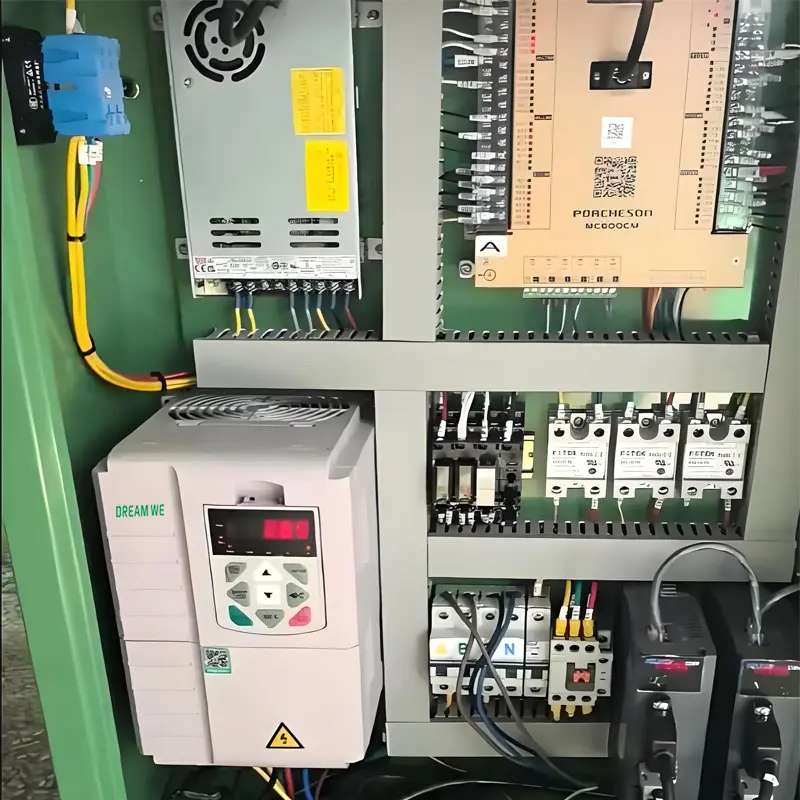

- Embedded installation (embedded in power distribution cabinets): If the power distribution cabinet itself has an IP54 protection rating, the inverter can use an IP20 rating (which only prevents finger contact). However, it is critical to ensure good heat dissipation inside the power distribution cabinet.

Step 3: Match Protection Levels by Scenario (Practical Examples)

| Application Scenario | Core Threat Factors | Recommended IP Rating | Additional Requirements |

|---|---|---|---|

| Ordinary workshops (e.g., assembly workshops) | Mild dust, no liquid contact | IP54 | Shell made of cold-rolled steel, with a dust filter |

| Food processing workshops (cleaning areas) | High-pressure cleaning water, humidity, slight dust | IP65 | 304 stainless steel shell, waterproof connectors |

| Underground mines (crushing sections) | Heavy dust, no liquid | IP66 | Fully sealed shell + forced air cooling, anti-vibration design |

| Outdoor pump stations (open-air) | Rain, sunlight, dust | IP65 + Sunshade | Built-in heater (for condensation prevention), low-temperature startup function |

| Chemical workshops (explosive zones) | Flammable and explosive gases, mild corrosive dust | IP54 + Ex d IIB T4 | Explosion-proof certification, anti-corrosion coating on the shell |

| Sewage treatment plants (near aeration tanks) | Humidity, sewage splashing, corrosive gases | IP65 | 316 stainless steel shell, waterproof terminal blocks |

Step 4: Avoid 3 Common Misunderstandings (Ensure Correct Selection)

-

Misunderstanding 1: “The higher the protection level, the better”

Excessively pursuing a high protection level (e.g., IP68) can lead to poor inverter heat dissipation. Fully sealed shells easily trap heat, which may cause overload faults. Additional heat dissipation modules (e.g., water cooling systems) are then required, increasing costs and potentially causing operational failures due to inadequate heat dissipation. It is important to balance “protection needs” and “heat dissipation efficiency”. For example, an IP65 rating is sufficient for dry and dusty environments—there is no need to choose IP68.

-

Misunderstanding 2: “Only focus on the IP rating and ignore material quality”

In corrosive environments (e.g., acid-base workshops), even if the IP rating meets standards, the shell will still corrode if it is made of ordinary cold-rolled steel. Therefore, it is necessary to specify requirements for shell materials (e.g., 304/316 stainless steel) and coatings (e.g., epoxy resin spraying) to avoid shortening the inverter’s service life due to material issues.

-

Misunderstanding 3: “Confusing the IP rating with the explosion-proof rating”

In explosive environments, an IP54 rating only prevents dust and water entry—it cannot block flammable and explosive gases from entering the inverter. Explosion-proof inverters (with Ex certification) must be selected. The IP rating only serves as a supplementary requirement for explosion-proof protection and cannot replace the explosion-proof rating.

Summary: 4-Step Process for Determining Protection Level

- List threats: Identify solids (dust), liquids (water/corrosive liquids), temperature, and special factors (explosion protection/outdoor use) in the environment.

- Check standards: Match the IP dust (first digit) and water (second digit) protection levels based on the identified threat factors.

- Add special requirements: For explosive environments, supplement with explosion-proof ratings; for outdoor environments, add sun protection/condensation prevention measures; for corrosive environments, specify material requirements.

- Balance heat dissipation: For high protection levels (IP6X and above), confirm whether the inverter is equipped with forced heat dissipation (air cooling/water cooling) to avoid insufficient heat dissipation.