How to Handle Variable Frequency Drive (VFD) Failure: A Comprehensive Troubleshooting Guide

Introduction

Variable Frequency Drive (VFD) failure can be a costly and dangerous issue in industrial settings. When a VFD malfunctions or “fails catastrophically,” it can lead to unplanned downtime, equipment damage, and potential safety hazards. This comprehensive guide outlines the immediate steps to take when facing a VFD failure, how to diagnose the root cause, and preventive measures to avoid future issues.

Immediate Safety Response

Power Isolation

- Cut power supply: Immediately shut off the main power supply to the VFD

- Confirm de-energization: Verify that all power indicators are off before proceeding

- Lockout/tagout: Use lockout/tagout procedures to prevent accidental re-energization

Hazard Assessment

- Evaluate environment: Check for smoke, fire, or hazardous fumes

- Use protective equipment: Wear appropriate PPE including gloves, safety glasses, and protective clothing

- Ventilate area: Ensure proper ventilation if smoke or fumes are present

- Fire safety: Have fire extinguishing equipment nearby if needed

Area Securing

- Post warning signs: Place warning signs around the affected area

- Restrict access: Prevent unauthorized personnel from approaching the faulty equipment

- Notify personnel: Inform supervisors, maintenance teams, and safety officers

Post-Failure Assessment

Visual Inspection

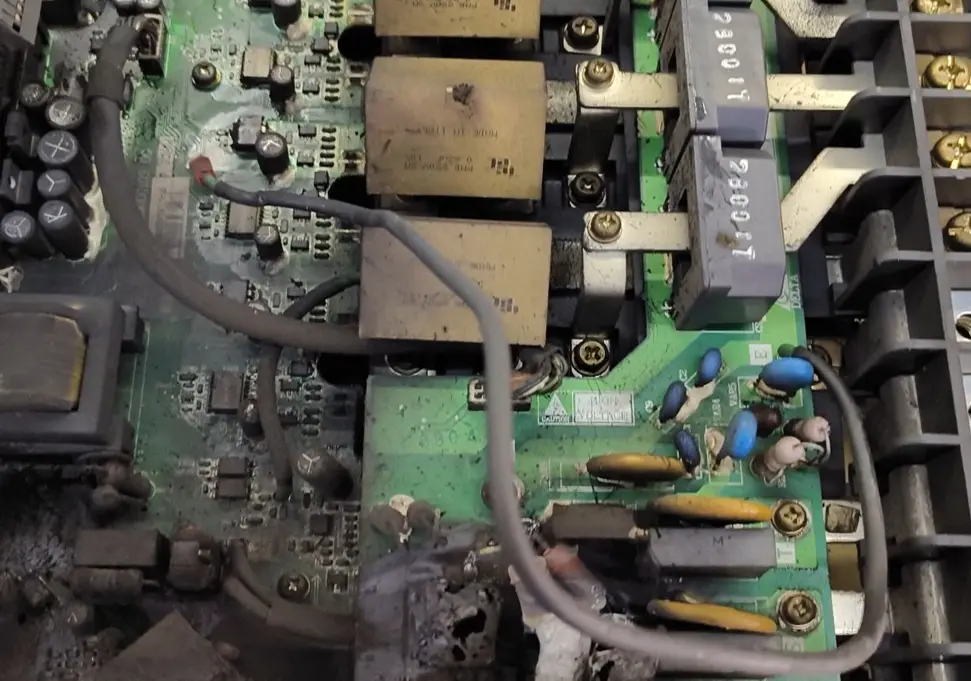

-

External examination:

- Look for signs of physical damage, burns, or deformation

- Check for blown fuses or tripped circuit breakers

- Inspect cable connections for damage or overheating

-

Internal inspection (only after complete cooling):

- Look for capacitor swelling or explosion

- Check for burnt components or PCB damage

- Inspect cooling fans and heatsinks for blockages

Documentation

- Photographic evidence: Take detailed photos of the failure from multiple angles

- Event timeline: Document the sequence of events leading to failure

- Data collection: Gather any available fault codes or diagnostic information

- Environmental factors: Note environmental conditions (temperature, humidity, etc.)

Root Cause Analysis

Electrical System Checks

- Power quality testing: Check for voltage fluctuations, harmonics, or transients

- Grounding verification: Verify proper grounding and bonding

- Insulation resistance: Test motor and cable insulation resistance

- Load evaluation: Evaluate load characteristics and any recent changes

VFD-Specific Diagnostics

- Fault code interpretation: Analyze any stored fault codes

- Parameter review: Check for incorrect parameter settings

- Thermal assessment: Inspect for overheating issues

- Component testing: Test key components like capacitors, IGBTs, and rectifiers

Common Failure Causes

-

Power-related issues:

- Voltage spikes or surges

- Power interruptions or brownouts

- Phase loss or imbalance

- Poor power quality

-

Environmental factors:

- Excessive temperature

- High humidity or moisture

- Dust, dirt, or contamination

- Vibration or shock

-

Mechanical problems:

- Motor failure or degradation

- Load issues or mechanical binding

- Coupling or belt problems

- Bearing failures

-

Operational factors:

- Overloading or frequent starts/stops

- Improper parameter configuration

- Inadequate maintenance

- Programming errors

Repair and Replacement Considerations

Professional Assessment

- Technical support: Engage manufacturer technical support if available

- Repair feasibility: Have qualified technicians assess repair options

- Cost-benefit analysis: Evaluate repair vs. replacement costs

- Downtime impact: Factor in production impact during repair

Temporary Solutions

- Backup equipment: Install backup VFD if available

- Temporary bypass: Implement temporary bypass solutions if possible

- Alternative control: Consider alternative motor control methods temporarily

- Production adjustments: Modify production processes to minimize impact

Preventive Maintenance Strategies

Regular Inspection Schedule

- Daily checks: Visual inspection and basic function checks

- Scheduled maintenance: Planned preventive maintenance activities

- Predictive maintenance: Implement condition monitoring techniques

- Component replacement: Proactive replacement of wear items

Environmental Controls

- Temperature management: Ensure proper cooling and temperature control

- Contamination prevention: Implement filtering and sealing measures

- Humidity regulation: Maintain appropriate humidity levels

- Ventilation systems: Ensure adequate ventilation and air quality

Operational Best Practices

- Training programs: Provide proper operator training

- Standard procedures: Develop and follow standard operating procedures

- Load management: Implement proper load management techniques

- Power quality improvement: Install power conditioning equipment if needed

Conclusion

Effectively handling VFD failures requires a systematic approach that prioritizes safety, thorough investigation, and preventive action. By following the steps outlined in this guide, facility managers and maintenance personnel can minimize downtime, reduce costs, and prevent future failures. Remember that VFDs are complex electronic devices, and professional assistance should be sought when necessary to ensure safe and effective resolution of issues.