How to Quickly Master the Core Technology of Frequency Converters

I. Break Through from Underlying Principles: Grasp the Core Logic of “Current Conversion + Speed Regulation”

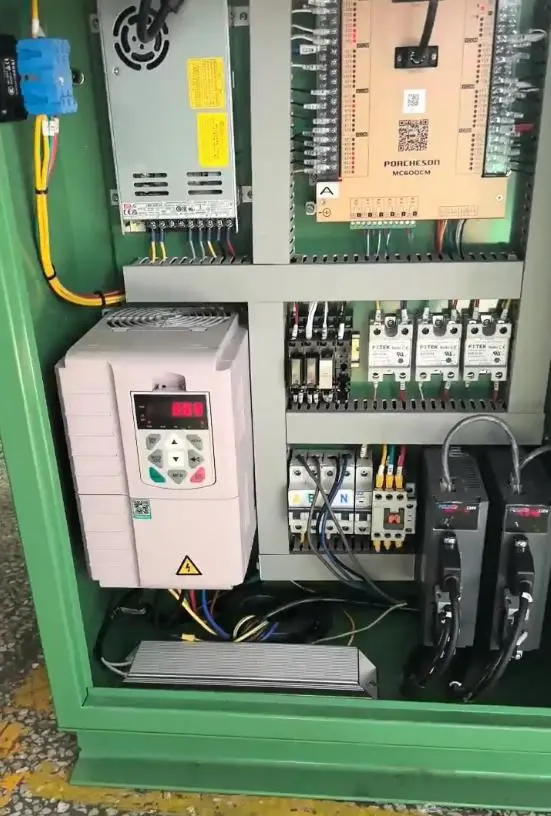

- Disassemble Core Circuit Modules

- Rectifier circuit: Focus on understanding how diode/IGBT rectifier bridges convert alternating current (AC) to direct current (DC). Remember the quick calculation: “Three-phase rectified output voltage ≈ 1.35 × input voltage”.

- Inverter circuit: Master the three-phase bridge inverter structure composed of 6 IGBTs, and understand how “Pulse Width Modulation (PWM)” generates AC with adjustable frequency and voltage by altering the switching frequency.

- Control circuit: Focus on the role of the MCU (Micro Control Unit) — receiving external signals (e.g., speed settings), calculating, and outputting PWM drive signals to achieve precise motor control.

- Thoroughly Understand the Speed Regulation Mathematical Model

Keep in mind the asynchronous motor speed formula: n = 60f(1-s)/p (n = speed, f = frequency, s = slip ratio, p = number of pole pairs). The formula intuitively shows that changing frequency (f) is the core of speed regulation, and voltage must change proportionally with frequency (V/F ratio) to avoid motor magnetic circuit saturation.

II. Focus on 3 Control Methods: A Technical Ladder from Basic to Advanced

- V/F Control (Must-Master for Beginners)

- Core logic: Maintain a constant voltage-to-frequency ratio to achieve “boost compensation at low frequencies” (solving insufficient starting torque).

- Quick application: Note that variable torque loads like fans and water pumps favor V/F control. During debugging, focus on setting the “V/F curve” (linear/square type) and “torque boost” parameters.

- Vector Control (Advanced Core)

- Core logic: Through coordinate transformation (Clarke-Park transformation), simplify the complex three-phase motor model into a “field current + torque current” DC motor model, enabling independent control of speed and torque.

- Key parameters: Master debugging techniques for “motor parameter self-learning” (requires no-load/load learning) and “speed loop PI regulator” (proportional gain/integral time) — critical for improving low-speed stability.

- Direct Torque Control (DTC, High-Level Application)

- Core logic: Without complex coordinate transformation, directly calculate flux and torque by detecting motor voltage and current, with a response speed over 10 times faster than vector control.

- Applicable scenarios: Equipment requiring fast dynamic response, such as cranes and elevators. During debugging, balance “torque ripple suppression” and “switching frequency”.

III. “Three Horizontal and Three Vertical” Memory Method for Key Parameters

Classified horizontally by “safety → performance → function” and vertically aligned with “motor → load → system” scenarios:

- Safety Parameters

- Motor protection: Overcurrent (150% rated current for 1 minute), overvoltage (DC bus voltage > 1.1× rated value), overheating (IGBT temperature > 85°C alarm).

- System protection: Undervoltage protection (grid fluctuation < 85% rated voltage), overload protection (thresholds set based on constant torque/variable torque loads).

- Performance Parameters

- Dynamic response: Acceleration/deceleration time (set by load inertia; e.g., conveyors need longer acceleration to prevent slipping), braking resistor capacity (formula: R ≥ U²/2P, where U = DC bus voltage, P = braking power).

- Precision control: Carrier frequency (high frequency reduces noise but increases loss; 8-12kHz for machine tools, 2-5kHz for fans), PID proportional band/integral time (20-50% proportional band recommended for constant-pressure water supply systems).

- Functional Parameters

- Communication parameters: Modbus address (default 1), baud rate (9600bps common), data format (8 data bits + 1 stop bit).

- Logic control: Multi-speed setting (3-16 speeds via terminal combination), forward/reverse rotation lockout (prevents equipment misoperation).

IV. Practical Verification: 3 Core Experiments for Quick Start

- Motor Parameter Self-Learning Experiment

- Steps: Connect the motor → set rated voltage/current/speed → select “static self-learning” → start learning → record calculated stator resistance, leakage inductance, etc.

- Purpose: Ensure the frequency converter matches the motor accurately, avoiding overcurrent or insufficient torque during operation.

- V/F Curve Debugging Experiment

- Scenario: Test with a fan load, set “linear V/F” and “square V/F” respectively, compare current and speed at the same frequency, and understand why the square curve is more energy-efficient (fan power is proportional to the cube of speed).

- Vector Control Low-Speed Operation Experiment

- Goal: Achieve stable operation below 5Hz (with 50% load).

- Key: Adjust “speed loop proportional gain” (increasing improves response but may cause oscillation) and “torque feedforward” parameters (compensate for low-speed friction loss).

V. Recommended Efficient Learning Resources

- Manual Focus Method: Choose a mainstream model and study its “functional parameter table” and “application cases” — more effective than skimming 10 textbooks.

- Fault Reverse Inference Method: Collect 10 common faults (e.g., overcurrent E.OC, overvoltage E.OV), analyze causes using the manual, and distinguish between parameter setting issues and hardware faults.

- Simulation Tools: Use MATLAB/Simulink to build a frequency converter model, visually observe PWM waveforms and current vectors, and accelerate understanding of abstract concepts.

With these methods, you can master core technologies in 1-2 months. Focus on “clear principles, key parameters, and practical verification” — avoid excessive theoretical details and prioritize application.