10/28/2025

Detailed Compatibility Selection Table for Frequency Converters & Leakage Protectors Application Scenario Frequency Converter Specification Recommended Leakage Protector Parameters Installation & Wiring Requirements Matching Accessories & Calculation Examples Key Notes Civil/Small Equipment (e.g., laboratory motors, household inverter air conditioners) – Power: ≤ 5.5kW – Carrier frequency: 2–8kHz – Typical model: INVT GD200A-2R2G-4 – Input current: 10A (for GD200A-2R2G-4) – Type: Type A (compliant with IEC 60755 standard) – Leakage Operating Current (IΔn): 30mA – Operating Time (tΔ): ≤ 0.1s – Rated Current (In): 1.2×10A = 12A (select 16A grade) – Brand recommendation: Siemens 5SU1 16A/30mA/A – Install on the input side (between the MCCB and converter input filter) – Maintain a spacing of ≥ 15cm between input and output cables; do not bundle them – Grounding resistance ≤ 10Ω (civil standard) – Use a 2.5mm² multi-strand copper ground wire – Accessories: Input EMC filter (small-capacity, ≤0.1μF) – Leakage calculation (for general products): IΔn ≥ 10×(Ig1+Ign+3×(Ig2+Igm)) Example: Ig1=0.11mA, Ign=0mA, Ig2=1.32mA, Igm=0.36mA → IΔn≥10×(0.11+0+3×1.68)=51.5mA (select a 30mA Type A anti-harmonic model) – Prioritize personal safety; AC-type protectors are forbidden (false tripping rate >80%) – Refer to the INVT GD200A series manual General Industrial Equipment (e.g., small pumps, fans) – Power: 5.5kW ~ 37kW – Carrier frequency: 5–10kHz – Typical model: Mitsubishi FR-D700-15K-CHT – Input current: 32A (for 15kW/380V) – Type: Type B (anti-harmonic/surge-resistant) – IΔn: 50–100mA – tΔ: ≤ 0.1s – In: 1.5×32A = 48A (select 63A grade) – Brand recommendation: Mitsubishi NV-C 63A/100mA/B – Route input and output cables through separate steel conduits with a spacing of ≥30cm – Grounding resistance ≤4Ω (industrial standard) – Ground wire cross-section: 4mm² (matches 63A rated current) – Keep the distance between the leakage protector and converter ≤5m – Accessories: Input EMC filter + DC reactor – Leakage calculation (for anti-harmonic products): IΔn ≥10×(Ig1+Ign+Igi+Ig2+Igm) Example: Ig1=0.15mA, Ign=0.5mA, Igi=1.2mA, Ig2=2.1mA,...

Details

10/27/2025

Can Frequency Converters Be Connected to Leakage Protectors? Comprehensive Guidelines 1. Core Compatibility Logic: Why Do Ordinary Leakage Protectors Fail? The high-frequency switching characteristics of frequency converters generate two types of special currents, which cause false tripping of traditional leakage protectors: Harmonic Leakage Current: The high-frequency switching (typically in the kHz range) of IGBT modules produces a large number of 3rd and 5th harmonics. These currents easily leak through the cable-to-ground capacitance. AC-type leakage protectors can only detect sinusoidal leakage currents and cannot identify harmonic components, which directly triggers false tripping. Stray Capacitive Current: There is distributed capacitance between the frequency converter’s output cables, the ground, and the motor housing. Under high-frequency voltages, capacitive currents (usually in the mA range) are generated; these superimpose on normal leakage currents and exceed the leakage protector’s operating threshold. Therefore, it is necessary to select types (Type A/Type B) that are compatible with non-sinusoidal leakage currents. Their key differences are as follows: Leakage Protector Type Applicable Scenarios Detectable Leakage Current Types Compatibility in Frequency Converter Scenarios Type AC Pure power-frequency equipment (e.g., ordinary motors, heaters) Sinusoidal AC leakage current Not recommended (false tripping rate > 80%) Type A Equipment with pulsating DC (e.g., frequency converters, rectifiers) Sinusoidal + pulsating DC leakage current Recommended for general scenarios (compatibility: 70%) Type B Equipment with high-frequency harmonics/smooth DC Sinusoidal + pulsating DC + high-frequency harmonic leakage current Recommended for complex industrial scenarios (compatibility: 95%) 2. Installation and Configuration: Details Determine Stability 1. In-depth Logic of Installation Location Installation on the Input Side (Grid Side): This is the preferred option, as it only detects leakage current on the grid side and avoids harmonic interference from the frequency converter. It is recommended to install the leakage protector between the main circuit breaker and the frequency converter’s input filter, forming...

Details

10/27/2025

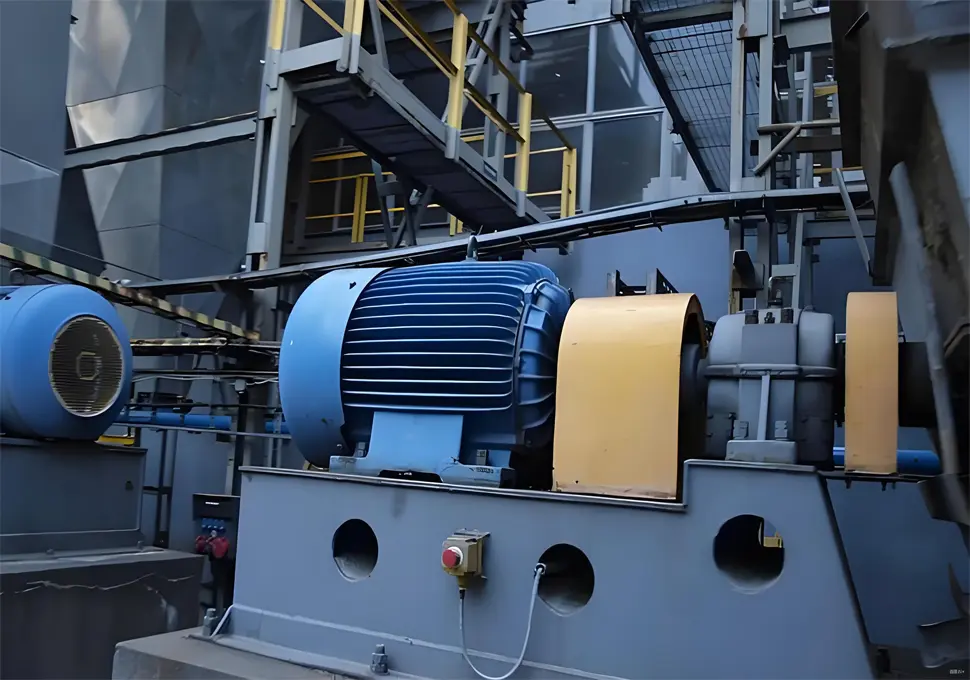

When a frequency converter drives a motor, vibration issues typically stem from three core categories: parameter mismatch, wiring/hardware problems, and load/mechanical issues. It is a common operational abnormality in variable frequency speed regulation systems. 1. Mismatched Parameter Settings (Most Common Cause) Incorrect input of motor parameters (e.g., rated voltage, frequency, pole count, stator resistance) that do not match the actual motor specifications, leading to deviations in the frequency converter’s control algorithm. In vector control mode, inadequate or incomplete motor self-learning fails to accurately identify the motor’s inherent characteristics, resulting in imprecise magnetic field orientation. An excessively low carrier frequency (typically recommended to be 2–10 kHz) causes high harmonic interference during low-frequency operation, triggering motor vibration. 2. Wiring and Hardware Issues Loose connections or poor contact on the frequency converter’s output side, or cables that are overly long or undersized, leading to three-phase voltage imbalance. Damaged IGBT modules, aging filter capacitors in the frequency converter, or inter-turn short circuits in the motor windings/bearing wear, which cause abnormal vibration during operation. Poor grounding allows harmonic interference to destabilize the motor’s magnetic field—an issue particularly noticeable during high-frequency speed regulation. 3. Load and Mechanical Transmission Issues Excessive misalignment between the motor and its load (e.g., pumps, fans, reducers) or loose/damaged couplings, resulting in mechanical impact-induced vibration. Load jamming, stalling, or frequent load fluctuations that the frequency converter cannot respond to in a timely manner, causing speed instability and vibration. Insufficiently secured motor bases, where the resonance frequency coincides with the operating frequency, amplifying vibration amplitude. 4. Operating Mode and Frequency Range Issues Motor operation in the low-frequency range (typically below 5 Hz) leads to insufficient torque and high harmonic content, easily causing “crawling vibration.” Failure to enable torque compensation or slip compensation functions results in unstable output torque during low-frequency operation, leading to...

Details

10/27/2025

Ten Major Advantages of Using Variable Frequency Speed Regulation This question is highly practical. Below are the ten core advantages of variable frequency speed regulation, covering key scenarios such as energy conservation, control, and operation and maintenance: 1. Significant Energy Savings and Lower Energy Costs When a motor operates at a non-rated speed, its energy consumption is proportional to the cube of the speed. Variable frequency speed regulation accurately matches load requirements, eliminating energy waste from the “big horse pulling a small cart” phenomenon. The energy-saving rate reaches 20%-50% in most applications. 2. Stepless Speed Regulation with High Control Precision It offers a wide speed regulation range (typically above 1:100) and enables continuous, smooth speed adjustment. It meets precise speed demands under different working conditions, far exceeding the adjustment accuracy of traditional methods like pole changing and voltage regulation. 3. Smooth Startup to Protect Motors and Equipment Adopting a soft-start method, the starting current can be controlled within 1.2 times the rated current. This avoids the large current impact during power frequency startup, reduces wear on motor windings and mechanical transmission components, and extends equipment service life. 4. Simplified Control Logic and Improved Automation It enables remote control and automatic speed adjustment via PLCs, touch screens, and other devices. It supports multi-speed operation and PID closed-loop control (e.g., pressure and flow closed-loop control), making it suitable for complex industrial automation scenarios. 5. Reduced Power Grid Impact During Startup The large current from power frequency startup causes grid voltage fluctuations, affecting other electrical equipment. Variable frequency soft start prevents this issue and ensures stable grid operation. 6. Enhanced Stability of Production Processes Precise speed control ensures consistent production parameters (such as flow, pressure, and tension). It minimizes product quality fluctuations, especially for high-process-demand scenarios like assembly lines, chemical production, and printing....

Details

10/24/2025

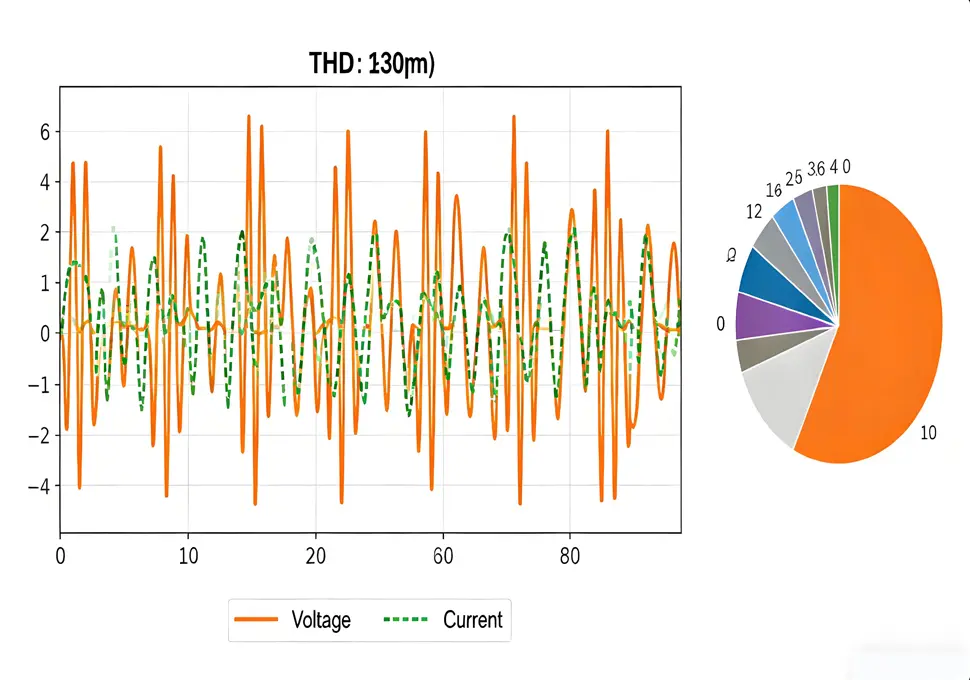

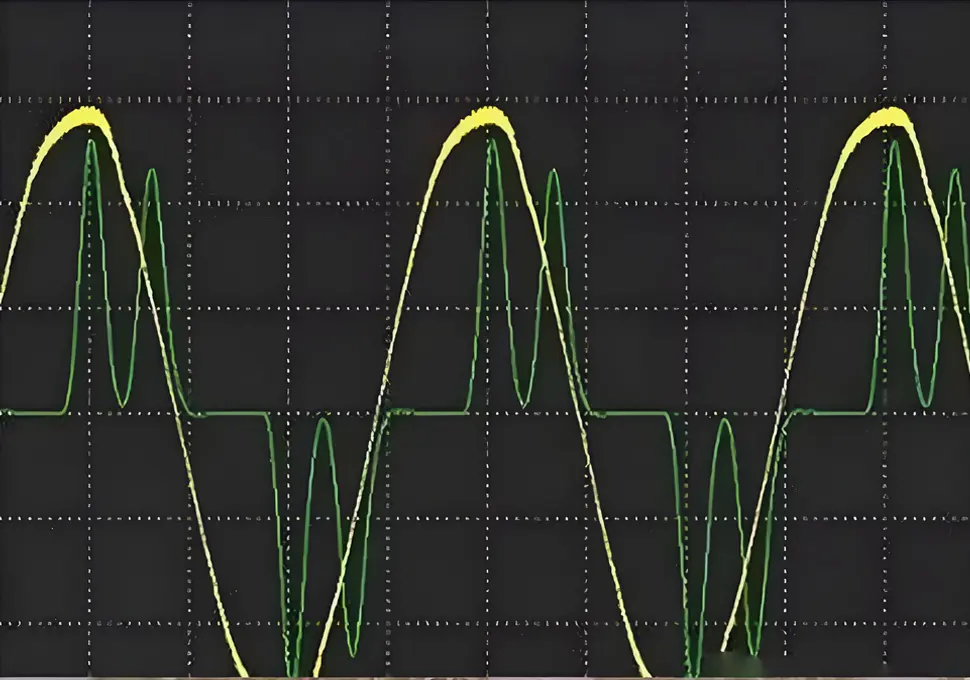

How to Detect VFD Harmonics?VFD Harmonic Detection Guide: Tools, Process & Standards for Industrial Users Detecting harmonics generated by Variable Frequency Drives (VFDs) is crucial for ensuring the stability of power grids and the safe operation of motor systems. This process involves selecting appropriate detection tools, formulating scientific testing plans, and analyzing data accurately. Below is a detailed, actionable detection guide tailored to B2B industrial scenarios (e.g., manufacturing plants, water treatment facilities) : I. Core Detection Tools & Equipment Selection Power Quality Analyzers (Primary Tool) Function: Professional instruments designed to measure voltage/current harmonics, THD (Total Harmonic Distortion), harmonic orders (up to 50th or 100th), and other key parameters. Recommended Models: Fluke 438-II, Yokogawa WT1800E, Chauvin Arnoux CA8335 (suitable for industrial environments with high anti-interference requirements). Application Tips: Choose analyzers with VFD-specific measurement modes to filter out carrier frequency interference and ensure data accuracy. Current/Voltage Sensors Current Sensors: Use clamp-on current transformers (CTs) or Rogowski coils (for large currents) to avoid breaking the circuit. Ensure the sensor’s frequency range covers 50/60Hz (fundamental) to at least 2kHz (high-order harmonics). Voltage Sensors: Employ voltage dividers or differential probes to measure line voltage, ensuring compatibility with the VFD’s output voltage range (e.g., 380V, 480V). Auxiliary Tools Data loggers: Record harmonic variations over long periods (e.g., 24 hours) to identify peak load harmonic characteristics. Oscilloscopes: Observe the waveform distortion of voltage/current to visually confirm harmonic presence (suitable for on-site troubleshooting). II. Step-by-Step Detection Process Pre-Detection Preparation Define Detection Objectives: Clarify whether to measure grid-side harmonics (VFD input terminal) or motor-side harmonics (VFD output terminal), and determine key parameters (THD, individual harmonic order content). Safety Check: Ensure the VFD is in normal operation, and wear insulated protective equipment (gloves, goggles) to avoid electric shock. Sensor Installation: Connect current sensors to the VFD’s input/output three-phase lines. Connect...

Details

10/24/2025

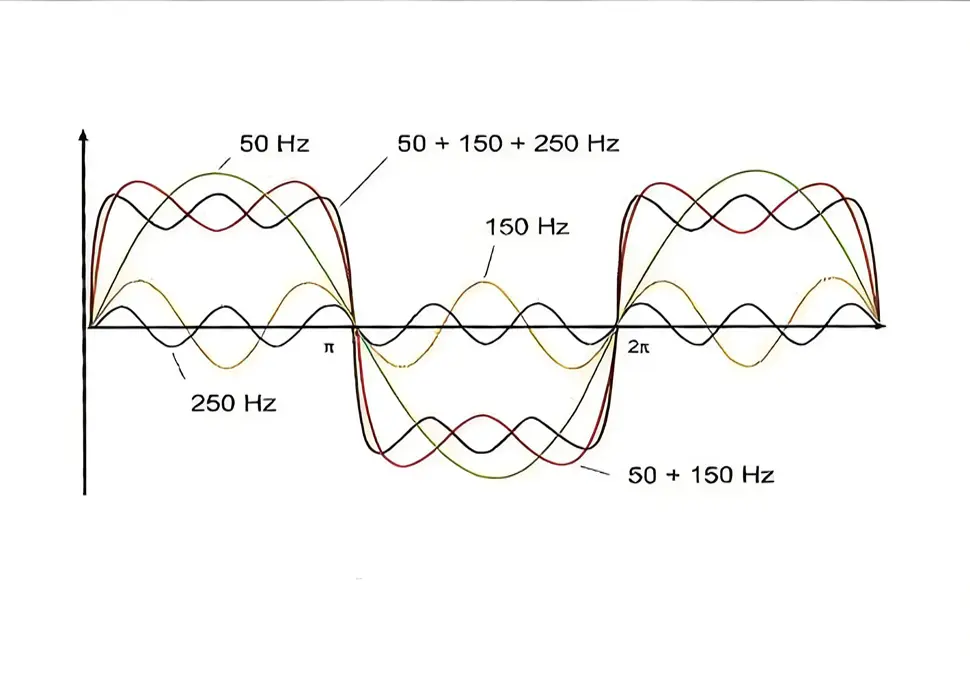

Harmonic Effects on VFD Motors: Causes, Impacts & Suppression Solutions Harmonics are voltage/current components in the power grid with frequencies that are integer multiples of the fundamental frequency. Generated by nonlinear loads such as Variable Frequency Drives (VFDs), they exert multi-dimensional negative effects on the operational performance, service life, and efficiency of motors (especially induction motors), as detailed below: I. Deterioration of Core Performance and Efficiency Significant Increase in Copper Loss and Iron Loss Copper Loss (Winding Loss): Harmonic currents generate additional Joule heat, and the loss is proportional to the square of the current frequency (Formula: \(P_{cu} \propto f^2\)). High-frequency harmonics cause a sharp rise in winding temperature. Iron Loss (Core Loss): Divided into eddy current loss and hysteresis loss. Eddy current loss is proportional to the square of the frequency, while hysteresis loss is approximately proportional to the frequency. Harmonics accelerate the alternating frequency of the core magnetic field, intensifying core heating and reducing the motor’s energy conversion efficiency. Practical Impact: When the motor’s input power remains constant, its output power decreases, and efficiency may drop by 5%-20% (depending on harmonic content), leading to increased operational costs. Torque Ripple and Unstable Speed The interaction between harmonic magnetic fields and the fundamental magnetic field generates “negative sequence torque” and “pulsating torque”: Negative sequence torque hinders motor rotation and reduces effective output torque; pulsating torque causes periodic speed fluctuations, resulting in vibration and noise, which impairs the precise control of motors (e.g., speed regulation in production lines, stable flow control of pumps). II. Increased Mechanical Wear and Shortened Service Life Aggravated Vibration and Noise If the harmonic frequency is close to the motor’s mechanical resonance frequency, resonance will occur, leading to a sudden increase in vibration amplitude. Long-term operation may cause mechanical failures such as bearing wear, rotor eccentricity, and frame...

Details

10/24/2025

Core Hazards of VFD Harmonics and Impact Scenarios In the process of converting alternating current (AC) to direct current (DC) and then inverting it back to adjustable-frequency AC, variable frequency drives (VFDs) generate non-sinusoidal harmonic currents and voltages. These harmonics pose multi-dimensional hazards to power systems, equipment, and production operations—especially in industrial B2B scenarios, where they may lead to severe economic losses and safety risks. Below is a detailed breakdown of specific hazards: I. Hazards to Power Systems Increased Grid Losses and Reduced Power Supply Efficiency Harmonic currents induce additional active power losses (including increased copper loss and iron loss) in power transmission lines, transformers, and other electrical equipment, which lowers grid transmission efficiency. Power companies must invest more to offset these losses, costs that may ultimately be passed on to enterprise users through electricity pricing. For regions with underdeveloped power grid infrastructure—such as Africa, Southeast Asia, and South America—this loss issue is more pronounced and can even worsen power shortages. Compromised Grid Voltage Quality and Voltage Distortion Harmonic voltages superimpose on fundamental voltages, causing voltage waveform distortion, fluctuations, and flicker. This undermines the stability of the entire power grid and may trigger malfunctions in sensitive equipment (e.g., precision instruments, PLC control systems), particularly impacting manufacturing production lines that rely on stable power supply. Interference with Relay Protection and Automatic Control Devices Harmonics can distort the operational logic of relay protection devices, fuses, and other equipment, leading to false tripping or failure to activate. In severe cases, this can escalate power grid faults and cause large-scale blackouts. For example, in factory power distribution systems, harmonics may trigger conflicts between VFDs and the protection devices of other equipment, disrupting production continuity. Malfunctions in Reactive Power Compensation Equipment Harmonic currents cause overcurrent and overheating in capacitor compensation devices, accelerating capacitor aging or...

Details

10/23/2025

Beyond Distance: What Other Factors Affect VFD and Motor Performance? In industrial drive systems, the performance of Variable Frequency Drives (VFDs) and motors is not only influenced by the cable distance between them but also by a combination of equipment parameters, environmental conditions, operational settings, and maintenance quality. These factors directly impact the system’s stability, energy efficiency, and service life—especially in complex industrial scenarios across target markets like Africa, Southeast Asia, and South America. Below is a detailed analysis of key influencing factors and their impacts: I. Equipment Parameter Matching 1. VFD and Motor Rating Compatibility Core Impact: Mismatched ratings between VFDs and motors are a primary cause of performance issues. For example, using a VFD with a lower power rating than the motor will lead to insufficient output torque, frequent overcurrent protection triggers, and even damage to the VFD’s power modules. Conversely, an oversized VFD may result in low-load operational inefficiency, increased harmonic distortion, and higher energy consumption. Key Requirements: Ensure the VFD’s rated current, voltage, and power match the motor’s specifications. For special scenarios (e.g., heavy starting loads in South American mines), select a VFD with a rated current 1.1–1.2 times higher than the motor’s. 2. Motor Type Adaptability Core Impact: Different motor types have varying compatibility with VFDs. Standard induction motors may experience increased iron loss and noise when operated at variable frequencies, while dedicated inverter-duty motors are designed with low-loss cores and reinforced insulation to handle high-frequency harmonics. Practical Suggestion: For long-term variable-speed operation, recommend inverter-duty motors to customers in target markets. If using standard motors, limit the frequency range (e.g., 5–50Hz) and reduce the carrier frequency appropriately. 3. Cable Quality and Specifications Core Impact: Beyond distance, cable quality and specifications significantly affect performance. Using aluminum-core cables instead of copper-core ones increases resistance and voltage drop,...

Details

10/23/2025

How to Determine the Distance Between a VFD and a Motor Cable? The distance between a Variable Frequency Drive (VFD) and a motor cable is not “calculated” through complex formulas, but rather a “reasonable laying distance” comprehensively determined based on factors such as equipment installation scenarios, electrical performance limitations, and engineering specification requirements. The core logic is to define the maximum allowable cable length or select suitable cables and auxiliary equipment according to actual installation needs, while ensuring the motor operates normally and avoiding performance losses and equipment failures. Below are the specific determination methods and key considerations: I. Core Determination Basis: Electrical Performance Limitations (Critical Conditions to Avoid Failures) 1. Voltage Drop Limitation (Most Basic Consideration) Cable transmission will cause voltage drop. If it exceeds 5% of the motor’s rated voltage, it will lead to insufficient motor torque and severe heating. The maximum allowable cable length can be estimated using the voltage drop formula: Voltage Drop Calculation Formula (Three-Phase Circuit): \(\Delta U = \frac{\sqrt{3} \times I \times L \times R_0}{1000}\) Parameter Explanations: \(\Delta U\): Maximum allowable voltage drop (V), usually 3%-5% of the motor’s rated voltage (e.g., for a 380V motor, the allowable voltage drop ranges from 11.4V to 19V); I: Motor rated current (A); L: Cable length (m); \(R_0\): Cable resistance per unit length (Ω/km), which can be found in cable specification tables (e.g., \(R_0≈17.5Ω/km\) for 1mm² copper core cables, and \(R_0≈4.4Ω/km\) for 4mm² copper core cables). Derived Formula for Maximum Allowable Cable Length: \(L = \frac{\Delta U \times 1000}{\sqrt{3} \times I \times R_0}\) Example: For a 380V motor with a rated current of 10A, using a 4mm² copper core cable (\(R_0=4.4Ω/km\)) and an allowable voltage drop of 5% (19V): \(L = \frac{19 \times 1000}{1.732 \times 10 \times 4.4} ≈ 248m\) That is, the cable length in this scenario is recommended not to...

Details

10/23/2025

What Are the Impacts of an Excessively Long Distance Between a VFD and a Motor Cable? An excessively long distance between a Variable Frequency Drive (VFD) and a motor cable can trigger a series of electrical performance issues, which may lead to equipment failure or shortened service life in severe cases. Especially in industrial B2B scenarios, such problems will directly affect production stability. The following is a detailed analysis of the specific impacts and core causes: I. Core Negative Impacts and Technical Principles 1. Output Voltage Distortion and Reduced Motor Efficiency Principle: Cables have distributed capacitance and inductance. During long-distance transmission, the PWM (Pulse Width Modulation) waveform output by the VFD will undergo reflection and distortion due to the cable’s parasitic parameters, resulting in an increase in the peak voltage at the motor terminal (i.e., a “voltage spike”) that exceeds the motor’s rated voltage tolerance range. Consequences: Increased iron loss and copper loss in the motor, severe heating, reduced actual output power, and higher energy consumption. For example, cables over 100 meters long may cause the voltage distortion rate to exceed 5% and motor efficiency to drop by 3%-10%. 2. Sharp Increase in the Risk of Motor Insulation Damage Principle: The peak value of voltage spikes can reach 2-3 times the VFD’s DC bus voltage (e.g., the peak voltage of a 380V VFD can exceed 1500V). Long-term exposure to such spikes will break down the insulation layer of the motor windings. Consequences: Motor faults such as inter-turn short circuits and ground leakage, and even direct motor burnout in severe cases. In the high-temperature and high-humidity environments of target markets like Africa and Southeast Asia, the insulation aging rate will accelerate further. 3. Aggravated Electromagnetic Interference (EMI) Principle: A long cable acts like an “antenna.” The high-frequency harmonics output by the...

Details

10/22/2025

I. Core Basis for Inverter Brake Resistor Selection The core function of an inverter brake resistor is to dissipate the regenerative energy of a motor. When the motor is in a deceleration, braking, or heavy-load lowering state (e.g., elevator descent, machine tool emergency stop), it acts as a generator and feeds energy back to the inverter’s DC bus. If this energy is not dissipated promptly, the bus voltage will rise excessively and trigger protection mechanisms. Selection should focus on “how to safely and efficiently dissipate regenerative energy,” with three core criteria: regenerative power, braking time, and allowable temperature rise. II. Key Parameters to Confirm Before Selection (Prerequisites) Before selecting a brake resistor, the following four types of basic parameters must be obtained, as they directly determine the resistor’s specifications: Rated Parameters of the Inverter and Motor Motor rated power \( P_{e} \) (kW, e.g., 5.5kW); Motor rated voltage \( U_{e} \) (V, e.g., 380V); Motor rated current \( I_{e} \) (A, can be estimated using \( P_{e} = \sqrt{3}U_{e}I_{e}\cos\varphi \), where \( \cos\varphi \) is 0.8~0.9); Inverter rated capacity \( S_{e} \) (kVA, usually matching the motor power—e.g., a 5.5kW motor typically requires an inverter with a capacity of approximately 7.5kVA). System Braking Requirements Braking type: Short-term braking (e.g., a single emergency stop of a machine tool) or continuous braking (e.g., frequent elevator up/down movements, crane load lowering); Braking time \( t_{b} \) (seconds, the time to decelerate from rated speed to a stop, e.g., 2s); Braking frequency: The number of braking cycles per unit time (e.g., 20 times per hour). Parameters of the Inverter’s Built-in Brake Unit If the inverter has a built-in brake unit (standard for most medium-to-high power inverters), check the manual to obtain the brake unit’s maximum allowable braking current \( I_{bmax} \) (A, e.g., 20A)...

Details

10/22/2025

Why Is the Inverter Fan Not Working? Causes and Impacts on the Inverter I. Common Causes of an Inverter Fan Not Working The inverter fan is a core heat dissipation component, and its failure to rotate is usually related to power supply issues, hardware faults, control logic errors, or the external environment. Specific causes can be categorized as follows: 1. Power Supply and Circuit Failures (Basic Troubleshooting Items) Broken fan power supply circuit: The fan is generally powered by the inverter’s internal auxiliary power supply (e.g., DC12V/24V). If the fuse in the power supply circuit blows, the terminal is loose, or the wire is broken, the fan will have no power input and stop rotating. For example, the fan power supply circuit of some inverters is in series with a small fuse, which may blow due to overload after long-term use. Faulty auxiliary power module: If the inverter’s internal auxiliary power supply (which powers the fan and control circuit) is damaged (e.g., capacitor bulging, chip burnout), it will directly cut off the fan’s power supply. This issue may also be accompanied by phenomena such as no display on the panel and abnormal control signals. 2. Fan Hardware Damage (High-Frequency Fault Points) Burnt fan motor: When the fan operates continuously for a long time, its motor windings may short-circuit or open due to insulation aging and bearing wear. Judgment method: After powering off the inverter, use a multimeter to measure the resistance of the fan motor windings. If the resistance is infinite (indicating an open circuit) or close to 0Ω (indicating a short circuit), the motor is damaged. Jammed fan bearings: Lack of oil in the fan bearings, excessive dust accumulation, or long-term wear will cause the rotor to jam and fail to rotate. Symptoms include significant resistance when manually rotating...

Details