08/19/2025

What is a Self-Priming Sewage Pump? A self-priming sewage pump is a specialized pump designed to transport sewage or wastewater containing solid particles, fibers, sludge, and other impurities, with inherent self-priming capabilities. Unlike traditional pumps, it does not require manual liquid filling into the pump casing before startup; instead, it can automatically draw in liquid through its unique structural design. It is widely used in municipal sewage discharge, industrial wastewater treatment, agricultural irrigation, construction site drainage, and other scenarios. I. Core Feature: Self-Priming Ability The key distinction between a self-priming sewage pump and a standard sewage pump lies in its self-priming capability. Ordinary centrifugal pumps must be primed (i.e., the pump casing and suction pipe filled with liquid) before startup to function; otherwise, they cannot pump water effectively. In contrast, self-priming sewage pumps—equipped with special structures like a built-in gas-liquid separation chamber—can automatically expel air from the pump and draw in liquid after inhaling a small amount of air during the first startup. For subsequent startups, re-priming is unnecessary, significantly enhancing operational convenience. II. Working Principle First Startup: A small amount of liquid is pre-stored in the pump (some models require manual addition of initial liquid, while others retain liquid automatically via their structure). When started, the impeller rotates, flinging out the liquid inside the pump while creating a vacuum in the suction pipe. Liquid Suction and Air Exhaust: External liquid is pushed into the suction pipe by atmospheric pressure. The gas-liquid mixture entering the pump is propelled toward the pump casing by centrifugal force. Air is expelled through the gas-liquid separation chamber, while the liquid flows back to the impeller, where it is flung out again. This process continues until all air is exhausted, enabling continuous pumping. Restart: A portion of liquid remains in the pump, allowing direct restart...

Details

08/19/2025

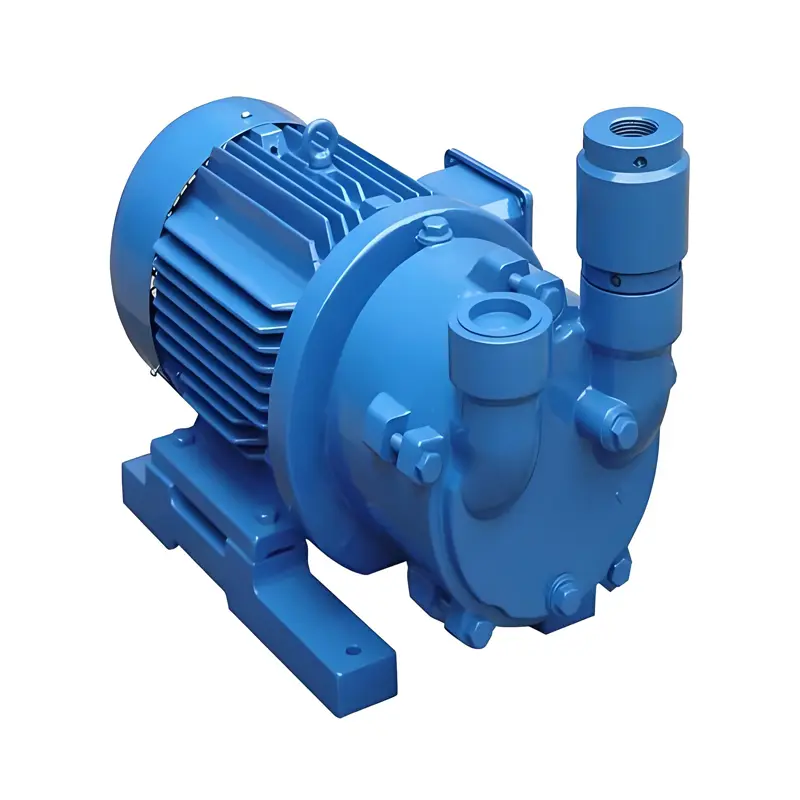

What Is a Dry-Type Sewage Pump? A dry-type sewage pump is a specialized pump designed to transport sewage containing solid particles, fibers, sludge, and other impurities. Its core rotating components (such as the motor and bearings) do not come into direct contact with sewage. Its design features a separation structure that isolates the motor from the sewage medium, preventing the motor from corrosion or damage caused by sewage—making it suitable for various harsh sewage environments. I. Core Structure and Working Principle The core structure of a dry-type sewage pump lies in “dry-wet separation,” mainly consisting of the following parts: Pump body: In direct contact with sewage, it contains an internal impeller. As the impeller rotates, it generates centrifugal force to suck in and discharge sewage. Motor: Serving as the power source, it connects to the pump body via a transmission structure (e.g., a coupling). The motor is completely isolated from sewage to prevent moisture damage, corrosion, or entanglement by impurities. Sealing device: At the connection between the pump body and the motor, mechanical seals or packing seals are typically used to prevent sewage from leaking into the motor compartment. II. Main Characteristics Strong corrosion resistance: The pump body is often made of cast iron, stainless steel, or engineering plastics, enabling it to resist sewage containing corrosive components such as acids and alkalis. Wide applicability: It can transport sewage with solid particles (e.g., sediment, gravel) and fibers (e.g., cloth strips, hair), making it ideal for municipal sewage treatment, industrial wastewater discharge, basement drainage, and more. Easy maintenance: Since the motor does not contact sewage, failure rates are low. Additionally, maintenance requires no direct contact with sewage, simplifying operations. Flexible installation: It can be installed in a fixed configuration (e.g., in a pump pit) or a mobile setup (e.g., portable sewage...

Details

08/19/2025

Submersible Sewage Pumps Submersible sewage pumps are devices designed to operate underwater for transporting sewage. They boast features like a compact structure and strong sewage-discharging capacity. Here’s a detailed overview: Structure and Working Principle Structure: The motor and pump are integrated into a single unit. The motor is powered via a cable, while the impeller and pump body are typically made from wear-resistant and corrosion-resistant materials. Working Principle: The motor drives the pump impeller to rotate, creating centrifugal force that draws in and discharges sewage. Key Characteristics Advantages: They have a compact structure and small footprint, allowing direct installation in sewage tanks without the need for a dedicated pump room. Installation and maintenance are convenient: small models can be installed freely, while large ones come with automatic coupling devices. They support long continuous operation. Since the pump and motor are coaxial, the shaft is short, rotating components are lightweight, and the bearing load is low. They eliminate issues like cavitation damage and the need for priming. Disadvantages: As they operate underwater and transport media containing solid materials, and given that the pump is close to the motor with a vertical arrangement, they have higher requirements than ordinary sewage pumps in terms of sealing, motor load capacity, bearing arrangement, and component selection. Scope of Application Industrial Applications: Suitable for factories, mines, and other sites, they can discharge industrial wastewater, mine sewage, etc. They are widely used in industries such as chemical engineering, petroleum, pharmaceuticals, mining, papermaking, cement plants, steel mills, and power plants to transport granular sewage and pollutants. Municipal Engineering: They can be used in drainage systems of urban sewage treatment plants, municipal drainage projects, construction site drainage, and more. Civil Buildings: Ideal for sewage drainage stations in residential areas, hospitals, hotels, and sewage discharge from high-rise buildings, among others....

Details

08/19/2025

What Is a Sewage Pump? A sewage pump is a type of pumping equipment specifically designed to transport sewage or wastewater containing solid particles, fibers, sludge, and other impurities. It is widely used in municipal engineering, industrial production, agricultural irrigation, construction sites, and domestic sewage disposal. Its core function is to handle the transportation of impurity-laden fluids. Compared with ordinary clean water pumps, it boasts stronger anti-clogging capabilities and durability. Core Features of Sewage Pumps Anti-clogging DesignSewage often contains impurities like sediment, paper scraps, hair, and fibers. Therefore, the flow passages (e.g., impellers and pump casings) of sewage pumps are usually designed to be wide and smooth to minimize impurity retention. Some impellers feature a cutting structure, which can chop fibers and small particles to prevent clogging. Corrosion ResistanceIndustrial sewage or chemical wastewater may contain corrosive substances such as acids and alkalis. The wetted components of sewage pumps (e.g., pump bodies and impellers) are made of corrosion-resistant materials like stainless steel and engineering plastics (PVC, PP) to extend their service life. Adaptability to Harsh Working ConditionsSewage pumps typically operate in humid, muddy environments or even those with flammable and explosive gases. As a result, their motor parts are designed with a sealed structure (e.g., IP68 protection rating) to prevent water or dust intrusion. Some models also have explosion-proof functions to meet the needs of special scenarios. Classification of Sewage Pumps (by Structure and Installation Method) Submersible Sewage Pumps: The motor and pump body are integrated, allowing them to submerge directly into sewage for operation without the need for additional suction pipes. They are suitable for low-liquid-level scenarios (e.g., sewage pools, catch basins) due to their easy installation and space-saving design. Dry-type Sewage Pumps (Horizontal/Vertical): The motor is separated from the pump body, which is installed on the ground or above...

Details

08/18/2025

What Is a Centrifugal Pump? A centrifugal pump is a fluid-handling device that moves liquids using centrifugal force. It is widely used in agricultural irrigation, industrial circulation systems, urban water supply, sewage treatment, and many other fields, making it one of the most common pump types. Core Components of a Centrifugal Pump A centrifugal pump consists of several key parts that work together to transport liquids effectively: Impeller: The rotating core component, typically fitted with curved blades and mounted on the pump shaft. It generates the centrifugal force needed to move liquids. Pump casing (volute): A spiral-shaped shell enclosing the impeller (resembling a snail’s shell). It collects the liquid thrown by the impeller and converts the liquid’s kinetic energy into pressure energy (i.e., increasing the liquid’s pressure). Pump shaft: Connects the motor to the impeller, transmitting rotational power from the motor to drive the impeller. Suction chamber: Located just before the impeller inlet, it guides liquid smoothly into the impeller, minimizing flow resistance and energy loss. Sealing mechanism: Such as mechanical seals or packing glands, which prevent liquid from leaking along the pump shaft. Motor: Serves as the power source, driving the rotation of the pump shaft and impeller. How a Centrifugal Pump Works The operation of a centrifugal pump relies on the generation and application of centrifugal force, following these steps: Priming before startup: Before the pump operates, the pump casing and suction pipe must be fully filled with liquid (a process called “priming”). If air is trapped inside, the low density of air means the rotating impeller cannot generate enough centrifugal force to create the necessary low pressure, preventing liquid from being drawn in (a problem known as “air binding”). Generating centrifugal force: The motor spins the impeller at high speeds (typically 1450 rpm or 2900 rpm)....

Details

08/18/2025

What Is a Submersible Pump? A submersible pump is a water-pumping device that operates with its pump body directly immersed in water. It is primarily used to extract liquids from deep wells, pools, rivers, lakes, and other water sources, and is widely applied in agricultural irrigation, industrial drainage, urban water supply, household drainage, and emergency rescue scenarios. Structural Features of Submersible Pumps Integrated design: The motor and pump are typically assembled into a single unit, eliminating the need for additional transmission components (such as couplings or drive shafts). Its compact structure allows for easy immersion in water. Waterproof sealing: The motor is equipped with robust waterproof sealing measures (e.g., mechanical seals, O-rings) to prevent water from entering the motor, which could cause short circuits or damage. Submersible operation: During operation, the entire pump body (including the motor) is fully submerged in liquid. This design uses the liquid to cool the motor while reducing suction-related inefficiencies, thereby improving pumping performance. Working Principle of Submersible Pumps When a submersible pump starts, the motor drives the impeller to rotate at high speed. Under centrifugal force, liquid within the impeller is propelled toward the impeller’s edge, creating a low-pressure zone at the impeller’s inlet. External atmospheric pressure then pushes liquid from the water source through the suction pipe into the impeller. The liquid is continuously expelled and transported to the desired location via the outlet pipe. Types of Submersible Pumps Based on application scenarios and structural differences, submersible pumps fall into several categories: Deep-well submersible pumps: Ideal for extracting water from deep wells. Their slender design enables them to adapt to deep water levels. Sewage submersible pumps: Specifically engineered to handle sewage, sludge, and other impurity-laden liquids. Their impellers and pump bodies feature anti-clogging designs. Clean-water submersible pumps: Used for pumping clean water...

Details

08/15/2025

What Is a Deep Well Pump? A Complete Guide to Its Types & Uses A deep well pump is a mechanical device specifically designed to extract liquids (primarily water) from deep wells, groundwater layers, or other deep water sources. Its design is characterized by the ability to adapt to relatively great depths for water extraction, making it widely used in scenarios such as agricultural irrigation, industrial water supply, urban water supply, and groundwater monitoring. Core Structure and Working Principle of Deep Well Pumps The structure of a deep well pump typically includes the pump body, motor, riser pipe, transmission shaft, and other components. Its working principle relies on centrifugal force or positive displacement transfer: Motor drive: The motor is usually installed on the ground and connected to the downhole pump body via a transmission shaft, providing power for pumping water. Liquid conveying: The pump body is positioned below the downhole water surface. When the motor starts, the impeller inside the pump body rotates at high speed, generating centrifugal force to draw water into the pump before transporting it to the ground via the riser pipe. Main Types of Deep Well Pumps Based on differences in working principles and structures, deep well pumps can be categorized into the following types: Centrifugal deep well pumps: The most common type, which pumps water through the centrifugal action of the impeller. They are suitable for medium to low-depth wells (usually tens of meters deep). Submersible electric pumps: The motor and pump body are integrated, allowing them to work entirely submerged in water without a long transmission shaft. They are ideal for deeper wells (up to hundreds of meters deep) and are easier to install and maintain. Screw-type deep well pumps: These transport liquids through the meshing movement of screws and bushings, making them...

Details

08/15/2025

How to Install Deep Well Water Pumps in Rural Areas: A Beginner’s Guide In rural areas where municipal water isn’t available, deep wells (often 50–300 feet deep) are lifelines for households, farms, and small communities. A properly installed deep well pump ensures reliable access to clean water for drinking, irrigation, and livestock. This guide walks through the entire process—from selecting the right pump to final testing—with tips tailored to rural conditions. Understanding Rural Deep Well Scenarios Rural deep wells come with unique challenges that influence pump selection and installation: Variable well depth: Wells may range from 50 feet (shallow deep wells) to over 300 feet, depending on the water table depth. Remote locations: Limited access to electricity (may rely on generators or solar) and professional services. Harsh conditions: Extreme temperatures, dust, and occasional flooding require durable equipment. Multi-purpose use: Water may need to serve homes, barns, and irrigation systems—demanding consistent pressure. For these scenarios, submersible deep well pumps are preferred over jet pumps. They’re submerged in water, more energy-efficient for deep depths, and less prone to priming issues—critical for remote areas. Step 1: Choose the Right Deep Well Pump Selecting the correct pump ensures efficiency and longevity. Key factors: 1. Well Depth & Water Level Measure the static water level (depth from ground to water when the well is unused) and total depth (ground to well bottom). Example: A well with a total depth of 200 feet and a static water level at 80 feet requires a pump rated for at least 120 feet of “lift” (distance from the water to the ground). 2. Flow Rate (GPM) Calculate based on usage: A 4-person household needs 10–15 GPM. Add 5–10 GPM for irrigation or livestock watering. 3. Power Source Electric: Most common if grid power is available (230V is standard for rural pumps). Solar: Ideal...

Details

08/14/2025

What Is a Jet Pump? A Complete Guide for Selection & Use Jet pumps are versatile water pumps widely used in residential, agricultural, and light industrial settings—especially for shallow to moderately deep wells, boosting water pressure, and transferring fluids. Unlike submersible pumps that operate underwater, jet pumps are installed above ground. They use a unique “jetting” mechanism to draw water from sources like wells, tanks, or lakes. Below is a detailed guide to help you understand how they work, their applications, and how to choose the right one. How Does a Jet Pump Work? A jet pump operates on Bernoulli’s principle—using high-velocity water flow to create low pressure (suction) that pulls water from a source. Here’s a step-by-step breakdown of its operation: Motor & Impeller: An electric motor drives an impeller, which pushes water through a narrow nozzle (the “jet”). Jet Action: The nozzle speeds up the water flow, creating a vacuum in the suction line connected to the water source. Water Intake: This vacuum draws water from the source into the pump, where it mixes with the high-velocity water from the nozzle. Pressure Boost: The combined water then flows into a diffuser, which slows the flow and converts its velocity into pressure, pushing the water through pipes to its destination. Key note: Most jet pumps need priming (filling the pump and suction line with water) to start—they can’t pull air, so that initial water charge is essential. Types of Jet Pumps Jet pumps are categorized by their design and intended use. The two most common types for residential and light commercial use are: 1. Shallow Well Jet Pumps Best for: Wells with water tables less than 25 feet (7.6m) deep. Design: Has a single impeller and a jet assembly mounted directly on the pump. Pros: Easy to install, lower cost,...

Details

08/13/2025

Water Pump Selection Guide: Centrifugal pump vs submersible pump: which one is more suitable for household water supply systems? When setting up a home water supply system (whether drawing from a well, tank, or municipal line), choosing between a centrifugal pump and a submersible pump depends on your specific needs—like water source depth, installation space, noise tolerance, and maintenance preferences. Below is a detailed comparison to help you decide. What Are Centrifugal and Submersible Pumps? 1. Centrifugal Pumps Working principle: Installed above ground, they use a rotating impeller to create centrifugal force, drawing water into the pump and pushing it through pipes. Key feature: Requires priming (filling the pump and suction pipe with water) to work—they can’t “suck” water from too deep without help. Typical use: Shallow water sources (wells ≤7m deep), tanks, or boosting pressure in municipal lines. 2. Submersible Pumps Working principle: Fully submerged in water (e.g., at the bottom of a well or tank), they push water upward using a hermetically sealed motor and impeller. Key feature: No priming needed—water surrounds the pump, so it starts instantly. Typical use: Deep wells (>7m), underground tanks, or where space above ground is limited. Core Comparison: Centrifugal vs. Submersible for Home Use To simplify your decision, here’s a side-by-side breakdown of key factors for home water supply: Factor Centrifugal Pump Submersible Pump Water Source Depth Best for shallow sources (≤7m). Limited by “suction lift” (max ~7m, due to atmospheric pressure). Ideal for deep sources (>7m). Can handle wells/tanks 10m–100m deep. Installation Installed above ground (needs a dry, sheltered spot near the water source). Requires a suction pipe from the source to the pump. Installed underwater (lower part of the well/tank). No need for a separate suction pipe—connected directly to the discharge pipe. Noise Level Noisier (motor and impeller run above ground; vibrations may...

Details

08/13/2025

Water Pump Selection Guide: How to choose a suitable water pump based on flow rate and head? When selecting a water pump, flow rate and head are the two core parameters that directly determine whether the pump can meet your actual needs. Choosing incorrect parameters may result in insufficient water supply, excessive energy consumption, or even equipment damage. Below is a detailed guide to selecting a pump based on flow rate and head, including key steps and considerations: I. Understanding Core Parameters: Flow Rate (Q) and Head (H) 1. Flow Rate (Q): Volume of Fluid Delivered Per Unit Time Units: Cubic meters per hour (m³/h), liters per second (L/s), or gallons per minute (GPM). Note conversions: 1 m³/h ≈ 0.278 L/s ≈ 4.403 GPM. How to calculate: Base it on your “total water demand” or “required delivery speed.” Example 1: A household with 3 bathrooms (each faucet uses ~0.6 m³/h) needs a total flow rate of at least 1.8 m³/h to meet simultaneous use. Example 2: For agricultural irrigation, if 1,000㎡ of land requires 5 m³ of water per mu (667㎡) per hour, the pump needs a flow rate of at least 5 m³/h. 2. Head (H): The Vertical Height a Pump Can Deliver Water (Including Resistance Loss) Units: Meters (m) or feet (ft), where 1 m ≈ 3.28 ft. What makes up total head? Actual (geometric) head: The vertical distance between the water source and the outlet. For example, pumping from a 10m-deep well to a 3m-high tank gives an actual head of 13m. Pipe resistance loss: Energy lost as water flows through pipes, valves, or elbows. This depends on pipe material, diameter, and length (typically 10%-30% of the actual head). Safety margin: Add 10%-20% to the total head to account for fluctuations (e.g., water level changes or pipe aging). Formula: Total Head = Actual Head...

Details

08/12/2025

How to choose a water pump and what precautions should be taken? Selecting a water pump is critical to ensuring its efficient, stable operation. The process requires comprehensive analysis of actual needs, medium properties, and environmental conditions. Below are detailed steps and considerations for pump selection: I. Core Steps for Water Pump Selection 1. Define Key Requirement Parameters This forms the foundation of selection. Accurately calculate or confirm the following: Flow rate (Q): The volume of fluid to be transported per unit time (e.g., m³/h, L/s). Determine based on specific scenarios: for instance, domestic water supply depends on peak water usage, while industrial lines rely on total equipment water consumption. Head (H): The total resistance the pump must overcome, consisting of three parts: Geometric head: Vertical height difference between the fluid’s source and destination (e.g., from a tank to a rooftop reservoir). Pipeline resistance: Friction in straight pipes (related to pipe diameter, length, and fluid velocity). Local resistance: Resistance from valves, elbows, tees, and other fittings.Note: Reserve a 10%-20% head margin during selection to account for potential resistance increases due to pipeline aging or changes in fluid viscosity. 2. Analyze Fluid Characteristics The physical and chemical properties of the fluid directly determine the pump type. Focus on: Fluid type: Clean water (e.g., tap water), sewage (with suspended solids), corrosive liquids (e.g., acids/alkalis), particle-laden fluids (e.g., sludge), or high-temperature fluids (e.g., boiler water). Key properties: Viscosity: High-viscosity fluids (e.g., oil, syrup) require positive displacement pumps (screw pumps, gear pumps) rather than centrifugal pumps, which are inefficient for thick fluids. Corrosiveness: Acidic or alkaline fluids need corrosion-resistant pumps (made of stainless steel, fluoroplastic, etc.). Solid content: Fluids with particles (e.g., sediment, waste) require sewage pumps (with cutting impellers or wear-resistant materials). Temperature: High-temperature fluids (e.g., >80℃) demand heat-resistant pumps (with...

Details