08/13/2025

Water Pump Selection Guide: How to choose a suitable water pump based on flow rate and head? When selecting a water pump, flow rate and head are the two core parameters that directly determine whether the pump can meet your actual needs. Choosing incorrect parameters may result in insufficient water supply, excessive energy consumption, or even equipment damage. Below is a detailed guide to selecting a pump based on flow rate and head, including key steps and considerations: I. Understanding Core Parameters: Flow Rate (Q) and Head (H) 1. Flow Rate (Q): Volume of Fluid Delivered Per Unit Time Units: Cubic meters per hour (m³/h), liters per second (L/s), or gallons per minute (GPM). Note conversions: 1 m³/h ≈ 0.278 L/s ≈ 4.403 GPM. How to calculate: Base it on your “total water demand” or “required delivery speed.” Example 1: A household with 3 bathrooms (each faucet uses ~0.6 m³/h) needs a total flow rate of at least 1.8 m³/h to meet simultaneous use. Example 2: For agricultural irrigation, if 1,000㎡ of land requires 5 m³ of water per mu (667㎡) per hour, the pump needs a flow rate of at least 5 m³/h. 2. Head (H): The Vertical Height a Pump Can Deliver Water (Including Resistance Loss) Units: Meters (m) or feet (ft), where 1 m ≈ 3.28 ft. What makes up total head? Actual (geometric) head: The vertical distance between the water source and the outlet. For example, pumping from a 10m-deep well to a 3m-high tank gives an actual head of 13m. Pipe resistance loss: Energy lost as water flows through pipes, valves, or elbows. This depends on pipe material, diameter, and length (typically 10%-30% of the actual head). Safety margin: Add 10%-20% to the total head to account for fluctuations (e.g., water level changes or pipe aging). Formula: Total Head = Actual Head...

Details

08/12/2025

How to choose a water pump and what precautions should be taken? Selecting a water pump is critical to ensuring its efficient, stable operation. The process requires comprehensive analysis of actual needs, medium properties, and environmental conditions. Below are detailed steps and considerations for pump selection: I. Core Steps for Water Pump Selection 1. Define Key Requirement Parameters This forms the foundation of selection. Accurately calculate or confirm the following: Flow rate (Q): The volume of fluid to be transported per unit time (e.g., m³/h, L/s). Determine based on specific scenarios: for instance, domestic water supply depends on peak water usage, while industrial lines rely on total equipment water consumption. Head (H): The total resistance the pump must overcome, consisting of three parts: Geometric head: Vertical height difference between the fluid’s source and destination (e.g., from a tank to a rooftop reservoir). Pipeline resistance: Friction in straight pipes (related to pipe diameter, length, and fluid velocity). Local resistance: Resistance from valves, elbows, tees, and other fittings.Note: Reserve a 10%-20% head margin during selection to account for potential resistance increases due to pipeline aging or changes in fluid viscosity. 2. Analyze Fluid Characteristics The physical and chemical properties of the fluid directly determine the pump type. Focus on: Fluid type: Clean water (e.g., tap water), sewage (with suspended solids), corrosive liquids (e.g., acids/alkalis), particle-laden fluids (e.g., sludge), or high-temperature fluids (e.g., boiler water). Key properties: Viscosity: High-viscosity fluids (e.g., oil, syrup) require positive displacement pumps (screw pumps, gear pumps) rather than centrifugal pumps, which are inefficient for thick fluids. Corrosiveness: Acidic or alkaline fluids need corrosion-resistant pumps (made of stainless steel, fluoroplastic, etc.). Solid content: Fluids with particles (e.g., sediment, waste) require sewage pumps (with cutting impellers or wear-resistant materials). Temperature: High-temperature fluids (e.g., >80℃) demand heat-resistant pumps (with...

Details

08/11/2025

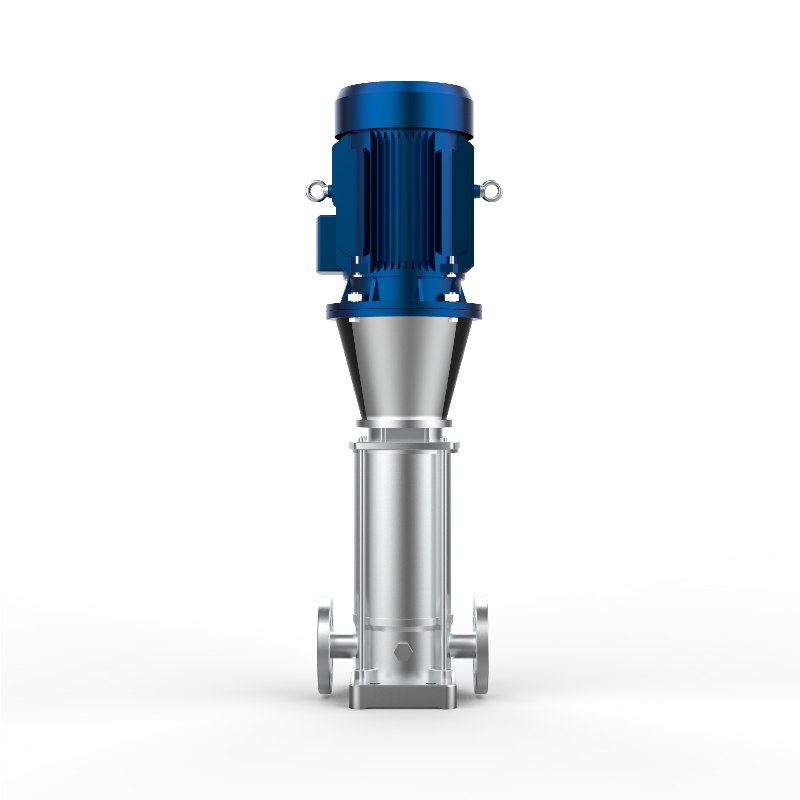

Centrifugal pumps are widely used fluid-handling devices in both industrial and residential settings, with classifications based on working principles, structural features, and application scenarios. Below are the four primary types: 1. Single-Stage Single-Suction Centrifugal Pump Structural Features: A single impeller is mounted on the pump shaft, and liquid is drawn into the impeller from only one side (single-suction design). Advantages: Simple structure, compact size, lightweight, low manufacturing costs, and easy maintenance. Applications: Ideal for low to moderate flow and head requirements, such as urban water supply/drainage, agricultural irrigation, and small-scale industrial cooling systems. Examples: Household clean water pumps, small industrial chillers. 2. Single-Stage Double-Suction Centrifugal Pump Structural Features: The impeller has suction inlets on both sides, allowing liquid to enter from two directions simultaneously. This design delivers approximately twice the flow rate of a single-suction pump of the same size, with a larger impeller diameter enabling higher head. Advantages: High flow capacity, efficient operation (dual-suction design reduces axial thrust), and stable performance. Applications: Suited for high-flow scenarios, including large water treatment plants, power plant circulating water systems, and agricultural irrigation stations. Examples: SH-type double-suction centrifugal pumps, split-case centrifugal pumps. 3. Multistage Centrifugal Pump Structural Features: Multiple impellers are connected in series on a single shaft. Liquid passes through each impeller sequentially, with total head increasing through “step-by-step pressurization” (total head ≈ head per impeller × number of impellers). Advantages: Exceptionally high head (capable of reaching hundreds or even thousands of meters), making it suitable for high-pressure fluid transfer. Applications: Used in high-head, medium-to-low flow situations, such as high-rise building water supply, mine dewatering, and boiler feedwater systems. Examples: D-type multistage centrifugal pumps, industrial boiler feed pumps. 4. Self-Priming Centrifugal Pump Structural Features: Equipped with a liquid storage chamber and a recirculation channel. No manual priming is needed before startup (though...

Details

08/11/2025

How to Select a Submersible Sewage Pump Selecting a submersible sewage pump requires comprehensive consideration of actual working conditions (such as medium characteristics, drainage requirements, and installation environment). Improper selection can lead to low efficiency, frequent failures, or even equipment damage. Below are detailed selection steps and key points, covering critical parameters and scenario-specific adaptation principles: 1. Clarify Medium Characteristics: Determine Pump Structure and Material Based on Sewage Composition The core function of a submersible sewage pump is to transport sewage. The physical and chemical properties of the medium directly influence the pump’s material, impeller design, and protective features. Focus on the following: Solid particle content and sizeIf sewage contains solids like sand, gravel, silt, or construction debris (e.g., construction site drainage, river dredging), choose an impeller with cutting/tearing capabilities (such as vortex impellers or single/double-blade cutting impellers) to prevent clogging. For particles larger than 50mm, ensure the flow passage diameter is at least 1.5 times the maximum particle size.Example: When pumping sewage with 20–30mm gravel, select a cutting-type pump with a flow passage diameter of ≥40mm. Fibers and viscous substancesFor wastewater with high levels of long fibers (e.g., hair, cloth strips, pulp in domestic sewage or dyeing wastewater), use anti-clogging impellers (e.g., open impellers, spiral impellers). Optimize the gap between the impeller and pump casing (typically ≤3mm) to reduce blockages from fiber entanglement. Corrosiveness and temperatureFor sewage containing acids/alkalis (e.g., chemical or electroplating wastewater) or high temperatures (over 60°C), upgrade materials accordingly: Mild corrosion (pH 6–8): Cast iron pump body + stainless steel impeller. Moderate corrosion (pH 4–10): All stainless steel (304 grade). Severe corrosion (pH <4 or >10): Special alloys (e.g., 316L) or rubber/lined plastic. High-temperature sewage (60–100°C): Use a high-temperature motor (insulation class ≥F) and replace standard rubber seals with fluororubber. Density and viscosityIf sewage density exceeds 1.2g/cm³...

Details

07/21/2025

What are the types of water pumps? There are many types of water pumps. According to different classification criteria (e.g. working principle, application, structure, etc.), the common types of water pumps are as follows: I. Classification according to working principle 1. Centrifugal pumps Characteristics: using impeller rotation to generate centrifugal force to transport liquid, large flow rate, moderate head. Applications: water supply, irrigation, industrial circulation systems (such as IS type, multi-stage centrifugal pumps). 2. Positive displacement pumps Gear pumps: squeeze the liquid through gear meshing, suitable for high viscosity fluids (such as lubricating oil, fuel oil delivery). Screw pumps: screw rotor to promote the liquid, low pulsation, suitable for particle-containing media (sewage treatment, oil industry). Plunger pump / piston pump: high pressure and small flow, used in hydraulic systems, cleaning equipment. 3. Axial flow pump Characteristics: liquid flows in axial direction, large flow, low head. Applications: farmland drainage and irrigation, river drainage (such as large pumping stations). 4. Mixed flow pump Features: between centrifugal pumps and axial pumps, medium flow and head. Applications: urban flood control, agricultural irrigation. 5. Swirl pump Features: impeller generates vortex effect, small flow, high head. Applications: household pressurization, small water supply system. Classification by use 1. Clean water pumps: conveying clean water (such as IS centrifugal pumps, submersible pumps). 2. Sewage pumps: handling liquids containing impurities and fibers (such as WQ submersible sewage pumps). 3. Chemical pumps: corrosion-resistant materials (such as fluorine plastic pumps, stainless steel pumps) for acid and alkali media. 4. Hot water pumps: high temperature resistant design (such as boiler feed pumps, HVAC circulating pumps). 5. Fire pumps: high head, fast response (such as XBD type fire pump). 6. Deep well pumps: long shaft or multi-stage design for deep well water extraction. C. Classification according to installation method 1. Submersible pump: motor...

Details