Shaft current in electric motors is a critical issue that can lead to premature equipment failure, increased maintenance costs, and unexpected downtime. This comprehensive guide explores the various causes of shaft current, its detrimental effects on motor performance, and effective prevention strategies to ensure reliable and efficient motor operation.

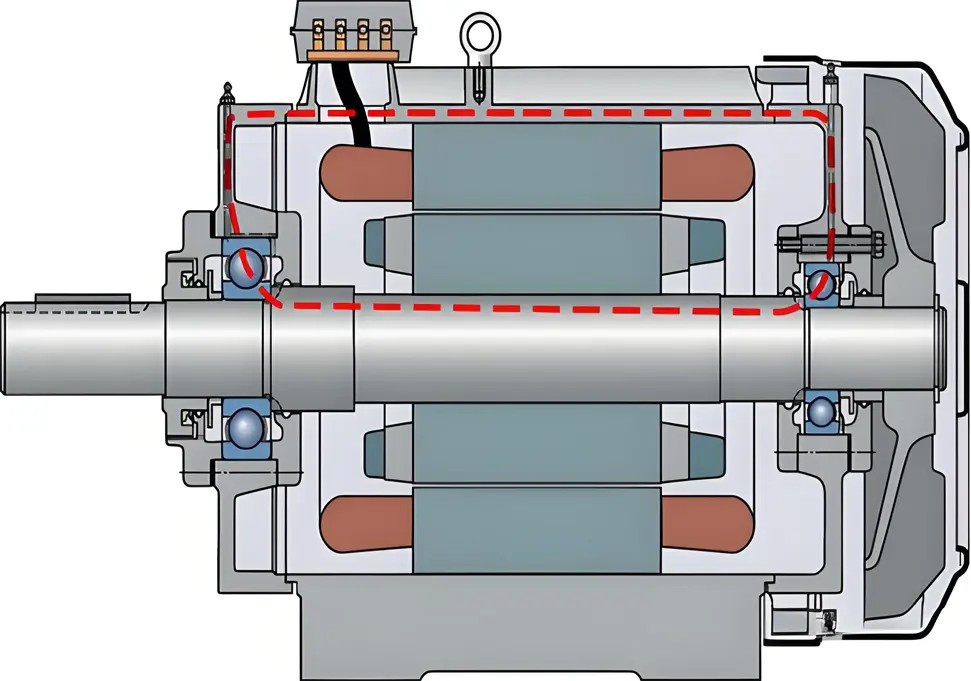

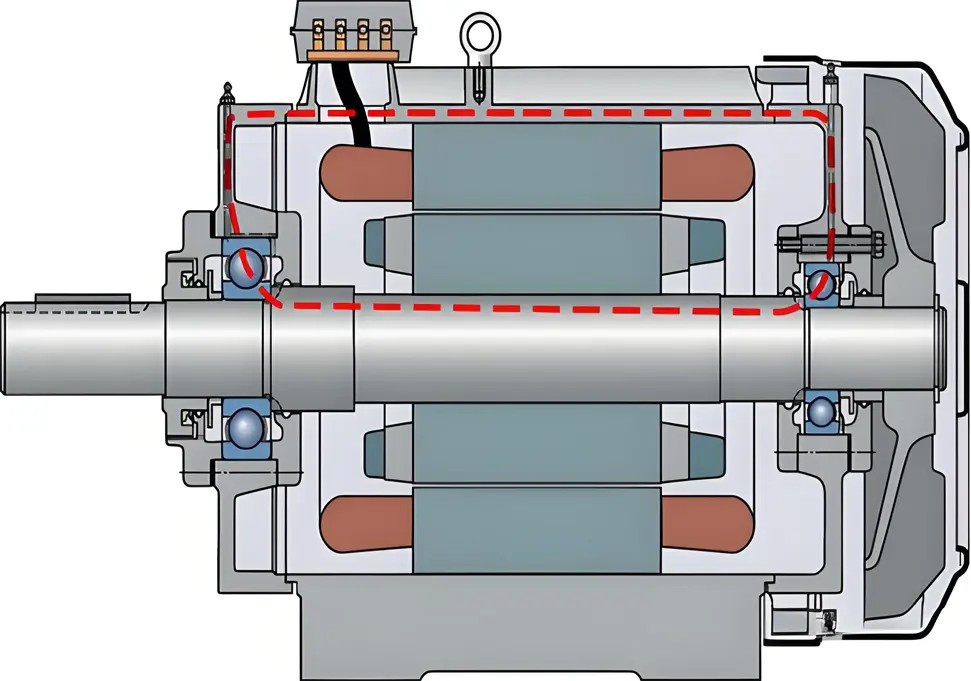

Shaft current refers to the flow of electrical current along the rotating shaft of an electric motor. This current typically travels from one end of the shaft to the other, or between the shaft and other motor components such as bearings and the motor frame. While motors are designed to be electrically neutral, various factors can create potential differences that initiate this unwanted current flow.

- Stator core irregularities: Manufacturing imperfections in stator core laminations

- Rotor misalignment: Eccentricity between rotor and stator creating uneven air gaps

- Core saturation issues: Localized magnetic saturation due to design flaws or overloading

- Winding faults: Short circuits or ground faults causing magnetic field distortions

- Triboelectric charging: Friction between shaft and bearings generating static electricity

- Belt-driven systems: Charge generation through belt-pulley friction

- Oil film breakdown: High-speed operation causing lubricant film breakdown

- Environmental conditions: Low humidity environments promoting static accumulation

- Variable frequency drive (VFD) harmonics: High-frequency components inducing shaft voltages

- Flux cutting: Rotating shaft cutting through magnetic fields

- Capacitive coupling: Voltage transfer between windings and shaft

- Common-mode voltages: Voltage imbalances in three-phase systems

- Improper grounding design: Inadequate or inconsistent grounding practices

- Multiple grounding points: Different potential levels at various grounding locations

- Ground loop formation: Current circulation within grounding systems

- Ground potential differences: Voltage variations between different earth points

- Voltage harmonics: Non-sinusoidal voltage waveforms creating additional magnetic fields

- Voltage imbalance: Uneven three-phase voltage distribution

- Transient voltages: Voltage spikes and surges

- Poor power factor: Inefficient power usage affecting motor performance

- Electrical discharge machining (EDM): Micro-arc discharges eroding bearing surfaces

- Pitting corrosion: Characteristic surface damage patterns

- Fluting: Groove formation on bearing raceways

- Lubricant degradation: Thermal breakdown of lubricating oils

- Efficiency reduction: Additional power consumption

- Vibration increase: Mechanical imbalance from bearing wear

- Temperature rise: Excessive heating affecting insulation

- Noise amplification: Mechanical deterioration causing increased operating sounds

- Electric shock hazards: Voltage presence on accessible surfaces

- Fire risks: Arcing potentially igniting flammable materials

- Equipment damage: Current transfer to connected machinery

- Production interruptions: Unexpected motor failures disrupting operations

- Symmetrical magnetic circuit design: Precision engineering of stator and rotor components

- Insulation enhancements: Strategic placement of insulating materials

- Electromagnetic shielding: Reduction of stray magnetic fields

- Grounding system optimization: Single-point grounding implementation

- Insulated bearings: Ceramic-coated or fully insulated bearing assemblies

- Shaft grounding devices: Carbon brush or fiber-based grounding systems

- Electrostatic discharge protection: Ionizers and static dissipative materials

- Common-mode filters: Reduction of VFD-generated harmonics

- Regular vibration analysis: Early detection of bearing damage

- Temperature monitoring: Identification of abnormal heating patterns

- Lubrication management: Proper lubricant selection and maintenance

- Insulation resistance testing: Periodic evaluation of electrical integrity

- Harmonic filters: Reduction of electrical harmonics

- Isolation transformers: Prevention of ground loops

- Surge protection devices: Mitigation of voltage transients

- Power factor correction: Optimization of electrical efficiency

- Contact and non-contact measurement techniques

- Recommended measurement locations

- Acceptable voltage levels by motor type

- Testing frequency guidelines

- Online monitoring solutions

- Threshold setting recommendations

- Trend analysis techniques

- Alarm system integration

- Vibration analysis patterns associated with shaft current

- Temperature profiling techniques

- Oil analysis for evidence of electrical discharge

- Ultrasonic testing applications

Effectively managing shaft current is essential for maximizing motor reliability and lifespan. By understanding the various causes and implementing appropriate prevention strategies, plant operators and maintenance professionals can significantly reduce the risk of premature motor failure. Regular monitoring, proper installation practices, and the use of specialized protective devices are key elements in maintaining optimal motor performance and minimizing operational costs.