Electro hydraulic servo drives and motors: advanced solutions for die-casting machines In today’s competitive manufacturing landscape, die casting operations face unprecedented challenges, including extreme operating conditions, increasing precision requirements, and the need for maximum production efficiency. The ES600 series was developed specifically to address these challenges with innovative servo motor technology designed for the unique demands of the die casting industry. The ES600 Advantage: Complete Industry Solution Technical Excellence Meets Practical Application The ES600 series represents the pinnacle of die casting machine technology. Our liquid-cooled embedded servo motors are engineered to deliver exceptional performance in even the harshest manufacturing environments. Key Technical Specifications Pressure oil pump displacement Motor Servo drive cc Model Model Parameter Model Parameter 16 32 EP18-70F17K 71Nm,1700rpm ES600T032 15KW 16 40 EP18-88F17K 88Nm,1700rpm ES600T037 18.5KW 16 50 EP18-105F17K 105Nm,1700rpm ES600T045 22KW 16 63 EP18-128F17K 128Nm,1700rpm ES600T060 30KW 16 80 EP18-168F17K 168Nm,1700rpm ES600T075 37KW 16 100 EP25-218F17K 318Nm,1700rpm ES600T091 45KW 16 125 EP25-267F17K 267Nm,1700rpm ES600T112 55KW Flexible Structural Configurations The ES600 series offers multiple structural configurations to meet your specific application requirements: Flat Key Design – Simple, reliable connection for standard die casting applications Spline Design – High torque transmission with axial movement capability Single-Output Shaft – Compact design for space-constrained installations Double-Output Shaft – Versatile solution for complex drive systems Performance Advantages That Transform Operations 1. Enhanced Weak Magnetic Overspeed Capability The innovative embedded structure significantly improves weak magnetic overspeed performance, allowing for higher operating speeds and increased production throughput. This translates directly to improved productivity and profitability. 2. Superior Demagnetization Resistance Advanced materials and proprietary design techniques ensure excellent resistance to demagnetization, even in the high-temperature, high-stress environments typical of die casting operations. This results in longer motor life and reduced maintenance costs. 3. Exceptional Overload Characteristics With the ability to handle short-term overloads up to 3 times rated capacity...

Details

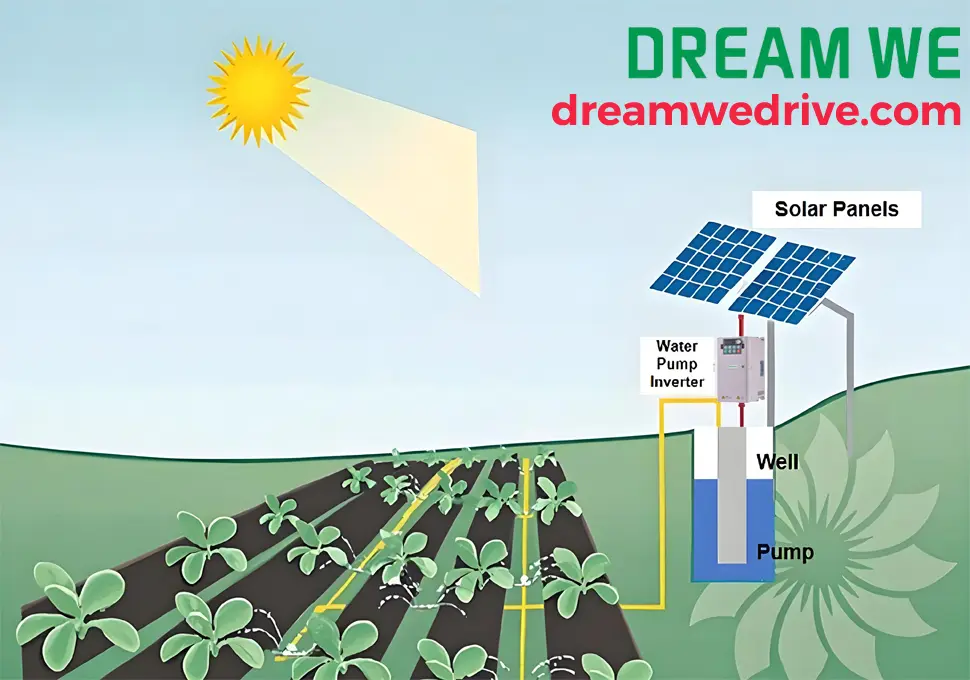

Dream We Solar-Powered Agricultural Irrigation System Solution: Features and Core Advantages Centered on “photovoltaic power supply + intelligent water control”, the Dream We Solar-Powered Agricultural Irrigation System addresses the pain points of traditional agricultural irrigation, such as heavy reliance on grid electricity, low water use efficiency, and high operating costs. By aligning with the irrigation needs of different crops (e.g., field crops, cash fruits, and protected agriculture), it provides an end-to-end solution covering “energy supply to precision irrigation”. Its features and advantages can be summarized in the following five dimensions: I. Core Features: Technical Design Adapted to Agricultural Scenarios 1. Self-Sufficient Photovoltaic Energy, Free from Grid Dependence Off-Grid/Grid-Tied Dual-Mode Design: The system supports two operating modes—”off-grid independent operation” and “grid-tied supplementary power supply”. It is suitable not only for remote fieldlands, mountainous areas, and orchards without grid access but also for grid-connected regions, where solar energy is prioritized for use and surplus electricity can be fed into the grid to generate revenue; Resilient Photovoltaic Modules: High weather-resistant solar panels (sandstorm-proof, corrosion-proof, and temperature-resistant) are adopted to adapt to open-air agricultural environments. For instance, they maintain stable power generation efficiency (with an annual degradation rate ≤ 2%) even in sun-scorched fieldlands or high-humidity greenhouses; Flexible Energy Storage Configuration: Optional lithium battery or lead-acid battery energy storage modules are available. Considering the agricultural irrigation characteristic of “concentrated water demand during daytime”, the system prioritizes real-time photovoltaic power. Surplus electricity is stored for backup, ensuring normal irrigation during low-light periods such as cloudy days or evenings. 2. Intelligent Precision Irrigation, Aligned with Crop Needs Multi-Sensor Linked Irrigation Control: It integrates soil moisture sensors (to detect soil water content), crop stem sensors (to monitor crop water demand), and weather stations (to collect data on rainfall, wind speed, and temperature). AI algorithms automatically adjust irrigation...

Details

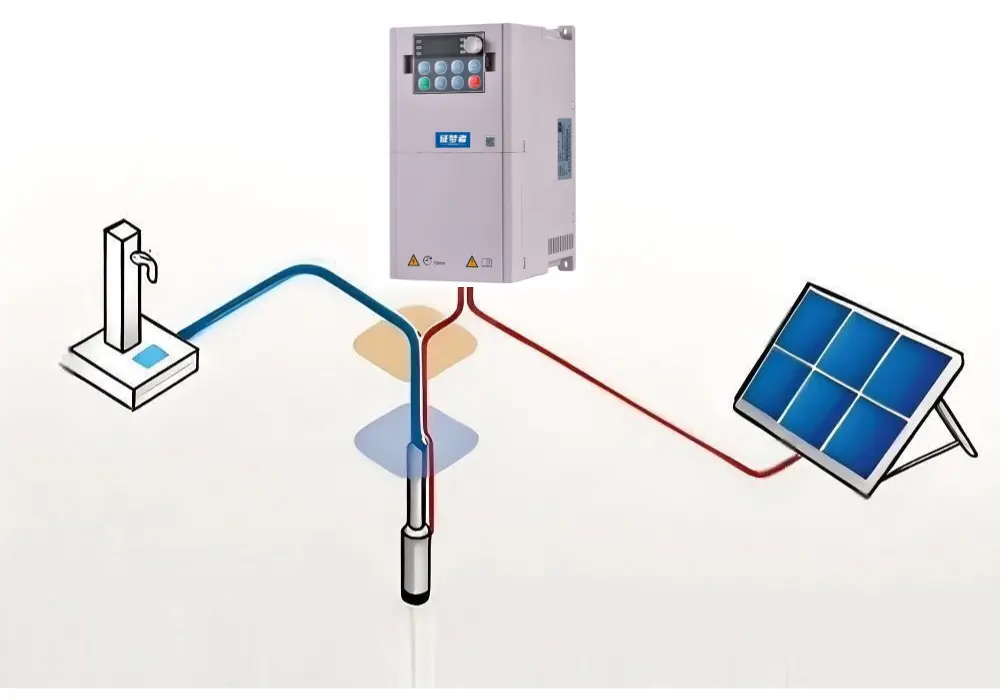

Solar Photovoltaic Inverter Water Pumping Solution: Efficiently Utilizing Clean Energy to Ensure Stable Water Supply In the context of uneven global water resource distribution, rising costs of traditional energy sources, and growing environmental protection demands, how to efficiently and environmentally friendly obtain and transport water resources has become a critical issue. The solar photovoltaic inverter-driven water pumping solution, with its clean, reliable, and cost-effective characteristics, provides an ideal water supply solution for agricultural irrigation, drinking water supply, groundwater regulation, and other applications, redefining sustainable water resource utilization models. I. Solution Core: Composition of the Solar PV Inverter-Driven Pumping System The solar PV inverter pumping system is based on the efficient conversion of “solar energy – electrical energy – mechanical energy,” with four key components working in tandem to form a complete water supply loop: Solar Photovoltaic Panels: As the energy input source, these panels utilize high-efficiency crystalline silicon or thin-film photovoltaic modules to automatically absorb solar energy and convert it into direct current (DC) based on sunlight conditions. Their installation angle can be optimized according to local latitude to maximize sunlight capture, ensuring basic power supply even on cloudy days. Solar photovoltaic inverter: The “smart hub” of the system, responsible for converting the direct current generated by the photovoltaic panels into alternating current required by the water pump (or stable direct current compatible with direct current water pumps), while also featuring maximum power point tracking (MPPT) functionality. By continuously monitoring light intensity and water pump load, it dynamically adjusts output power to ensure solar energy utilization remains at peak levels, preventing energy waste. Pump equipment: Select from types such as submersible pumps, submersible pumps, or centrifugal pumps based on the application scenario, ensuring precise matching with the inverter’s output parameters. For example, in groundwater extraction scenarios, submersible pumps can handle...

Details