Ultimate Guide: How to Identify Brushless vs Brushed Motors

When working with electric motors, being able to distinguish between brushless and brushed technologies is essential for proper maintenance, repair, and replacement decisions. This comprehensive guide outlines proven methods to identify motor types through visual inspection, structural analysis, and operational testing.

Visual Inspection Techniques for Motor Identification

Examining Motor End Construction

-

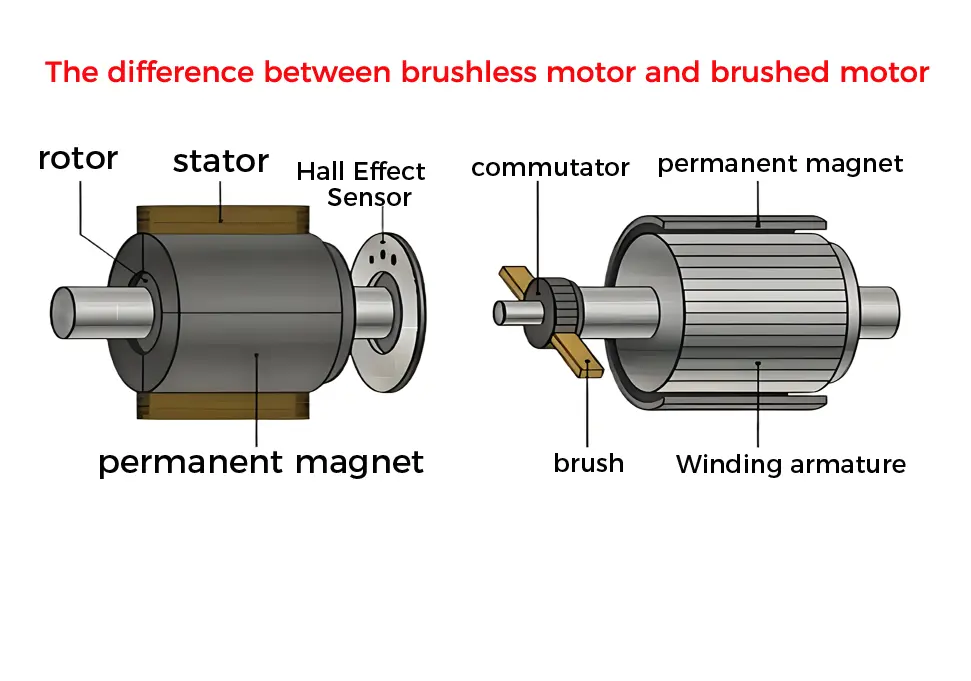

Key Brushed Motor Features

- Distinctive metal or plastic end caps designed to house the brushes and commutator assembly

- Access panels or removable sections for brush inspection and replacement

- Longer axial length to accommodate the commutator mechanism

- Visible brush wiring on smaller motor models

-

Identifying Brushless Motor Designs

- Smooth, uniform end caps without protrusions or access openings

- Compact overall dimensions with shorter axial profile

- Integrated Hall sensor connectors on the motor housing

- Heat sink features on the exterior casing for thermal management

Analyzing Terminal Connections

-

Brushed Motor Wiring Patterns

- Typically feature only two primary power terminals (positive and negative)

- May include additional terminals for speed control or braking functions

- Minimal terminal count, generally fewer than 4 connections total

- Simple wiring configuration without complex connectors

-

Brushless Motor Connection Characteristics

- Three main power phase terminals (usually labeled U, V, W or A, B, C)

- Multiple signal terminals (5-8) for Hall effect sensors

- Higher terminal count, typically 8-12 connections

- Complex multi-pin connectors rather than individual terminals

Structural Analysis Methods

Size and Weight Comparison

-

Brushed Motor Physical Traits

- Larger overall dimensions for equivalent power ratings

- Heavier rotor assembly containing windings and commutator

- Higher rotational inertia affecting performance characteristics

- Bulkier construction with less efficient use of space

-

Brushless Motor Design Advantages

- Superior power density with smaller footprint for same power output

- Lighter rotor assembly utilizing permanent magnet technology

- Lower rotational inertia enabling faster response times

- Compact, space-efficient construction

Thermal Management Features

-

Brushed Motor Cooling Systems

- Primarily rely on natural convection through motor housing

- Basic cooling fans on larger power models

- Limited thermal management requirements due to lower efficiency

- Simple heat dissipation through external casing

-

Brushless Motor Temperature Control

- Advanced cooling solutions including heat sinks, fans, or liquid cooling

- Optimized housing designs with thermal management features

- Enhanced heat dissipation requirements due to higher power density

- Sophisticated thermal monitoring systems on premium models

Controller and Drive System Analysis

Evaluating Control Components

-

Brushed Motor Control Requirements

- Simple speed controllers or basic on/off switches

- Compact, low-cost control electronics

- Direct integration with motor or power supply

- Minimal functionality beyond basic speed regulation

-

Brushless Motor Control Complexity

- Require dedicated electronic speed controllers (ESC)

- Larger control units with heat sinks and power components

- Advanced programming capabilities and tuning options

- Clear labeling indicating “Brushless ESC” or “BLDC Controller”

Operational Differences

-

Brushed Motor Operation

- Direct connection to DC power source possible

- Direction reversal through polarity change

- Speed regulation through voltage adjustment

- Simplified control without complex electronics

-

Brushless Motor Operation

- Dependence on specialized controller for proper function

- Direction control through programming rather than wiring

- Sophisticated algorithms for speed and torque regulation

- Integration with advanced control systems

Performance and Sound Analysis

Acoustic Signature Identification

-

Brushed Motor Sound Characteristics

- Audible brush contact during startup and operation

- Noticeable “hum” that varies with rotational speed

- Commutator friction sounds at lower velocities

- Increasing noise levels as brushes wear over time

-

Brushless Motor Operational Sounds

- Near-silent operation with only bearing noise audible

- Minimal electromagnetic humming even at high speeds

- Consistent noise levels throughout service life

- High-frequency controller sounds distinct from motor operation

Performance Trait Comparison

-

Brushed Motor Performance Limitations

- High starting torque with strong low-speed performance

- Efficiency degradation at higher operating speeds

- Visible sparking during operation

- Limited speed range with reduced performance at extremes

-

Brushless Motor Performance Advantages

- Smooth operation with moderate starting torque

- Consistent efficiency across entire speed range

- Spark-free operation with minimal electromagnetic interference

- Wide speed range with precise control capabilities

Maintenance and Environmental Considerations

Service Requirement Analysis

-

Brushed Motor Maintenance Needs

- Regular brush inspection and replacement (every 1000-3000 operating hours)

- Commutator cleaning and maintenance

- Frequent service intervals increasing long-term costs

- Higher maintenance requirements affecting reliability

-

Brushless Motor Maintenance Advantages

- Minimal regular maintenance requirements

- Extended service intervals (10,000-20,000 operating hours)

- Reduced long-term maintenance costs

- Higher reliability through simplified design

Environmental Suitability

-

Brushed Motor Environmental Limitations

- Sensitivity to dust, moisture, and corrosive elements

- Brush wear generates contamination in clean environments

- Spark risk makes them unsuitable for hazardous locations

- Limited protection ratings restricting application range

-

Brushless Motor Environmental Resilience

- Enhanced protection against harsh environmental conditions

- Sealed designs suitable for wet or dusty environments

- Spark-free operation approved for hazardous locations

- Higher IP ratings for versatile application possibilities

Practical Identification Strategies

Price and Application Context

-

Brushed Motor Market Position

- Lower initial cost appealing for budget-conscious applications

- Common in basic appliances, power tools, and toys

- Limited power range typically below 10kW

- Cost advantage offset by higher long-term ownership costs

-

Brushless Motor Application Domains

- Higher initial investment justified by performance benefits

- Preferred technology in automotive, aerospace, and industrial automation

- Wide power range from fractional horsepower to megawatt sizes

- Lower total cost of ownership despite higher upfront expense

Documentation and Label Verification

-

Motor Identification Labels

- Look for “BLDC” (Brushless DC) or “Brushed” designations on nameplates

- Model numbers often include “BL” prefix for brushless designs

- Check for “Commutator” references indicating brushed construction

- Review technical specifications for efficiency ratings

-

Documentation Analysis

- Brushless motors typically specify higher efficiency ratings (85%+)

- Brushed motor documentation references brush replacement intervals

- Controller requirements indicate motor type

- Wiring diagrams reveal terminal configurations

Step-by-Step Identification Process

-

Visual Inspection Protocol

- Examine motor end caps for brush access features

- Count terminal connections (more than 6 suggests brushless)

- Check for Hall sensor connectors on housing

- Evaluate overall size and construction complexity

-

Functional Testing Procedures

- Listen to startup and operation sounds

- Check for controller requirements

- Evaluate speed control precision

- Assess maintenance history and requirements

-

Documentation Review

- Examine motor nameplate for technology indicators

- Review maintenance requirements in technical documentation

- Analyze controller specifications

- Verify application context and typical usage patterns

By systematically applying these identification methods, technicians and engineers can accurately determine motor type, enabling appropriate maintenance, repair, and replacement decisions.