Variable Frequency Drives (VFDs) are essential components in modern industrial automation, providing precise control of motor speed and torque. However, when dealing with high-inertia loads or frequent braking requirements, proper selection of braking units and resistors becomes critical to ensure system reliability and performance.

Before selecting a braking unit for your VFD system, it’s important to determine if one is actually needed. The following scenarios typically require braking units:

Applications such as centrifuges, large fans, and water pumps generate significant regenerative energy during deceleration that must be dissipated.

Equipment like cranes, elevators, and conveyors that require frequent starting, stopping, or reversing benefit from proper braking systems.

When process requirements specify deceleration times less than 1/3 of the natural stopping time, braking units become necessary.

Vertical movement systems such as lifts and cranes continuously generate regenerative energy when lowering loads.

- Low-inertia loads (small fans, pumps)

- Applications with infrequent braking requirements

- Systems with adequate natural deceleration time

- Small-power VFDs with sufficient built-in braking capacity

P = (J × Δω²) / (2 × t) × η

Where:

- J = Moment of inertia (kg·m²)

- Δω = Angular velocity change (rad/s)

- t = Deceleration time (s)

- η = Mechanical efficiency

PE = G × V × 9.81

PW = PE × (1 - n)

Where:

- PE = Power from descending potential energy

- G = Weight of load (kg)

- V = Descending speed (m/s)

- PW = Braking power required

- n = Internal loss coefficient (typically 20%)

Where:

- U = Braking unit operating voltage (V), typically 700V

- P = Braking power (W)

P_resistor = P_braking × Kc × S

Where:

- Kc = Braking duty cycle coefficient

- S = Safety factor (typically 1.4)

Many VFD manufacturers integrate braking units into their drives, especially for smaller power ratings:

Models below 30kW at 380V include built-in braking units

Models from 0.12kW to 75kW feature integrated braking capability

Certain models include built-in braking resistors

For larger power ratings or specific applications, external braking units are typically required:

- 380V systems above 37kW

- 660V/690V systems (all power ratings)

- Siemens MM440 models above 75kW

- Specialized high-performance applications

- Motor power: 30kW

- Deceleration time: 5 seconds

- Braking frequency: 10%

- System voltage: 380V

- Calculate braking power: P = 30kW × 0.7 = 21kW

- Determine resistance: R = 700² / 21,000 ≈ 23Ω

- Calculate resistor power: P_resistor = 21kW × 10% × 1.4 = 2.94kW

23Ω, 3kW braking resistor with appropriate mounting hardware

- Maximum load: 500kg

- Descending speed: 0.4m/s

- Operating cycle: 30 seconds

- Descending time: 6.25 seconds

- Potential energy power: PE = 500 × 9.81 × 0.4 = 1962W

- Required braking power: PW = 1962 × (1-0.2) = 1570W

- Average braking power: P_avg = 1570 × 6.25 / 30 ≈ 327W

450Ω, 500W braking resistor with heat sink

- Keep braking unit within 5 meters of VFD

- Limit resistor wiring to 10 meters maximum

- Use shielded cables or twisted pair wiring

- Ensure proper polarity connections

- Follow manufacturer’s wiring diagrams

- Install in well-ventilated locations

- Use flame-retardant materials nearby

- Provide adequate heat dissipation space

- Install protective covers for high-temperature components

- Consider ambient temperature ratings

- Disable DC voltage controller

- Set appropriate braking voltage thresholds

- Adjust braking intensity parameters

- Configure duty cycle limits

- Test and optimize settings

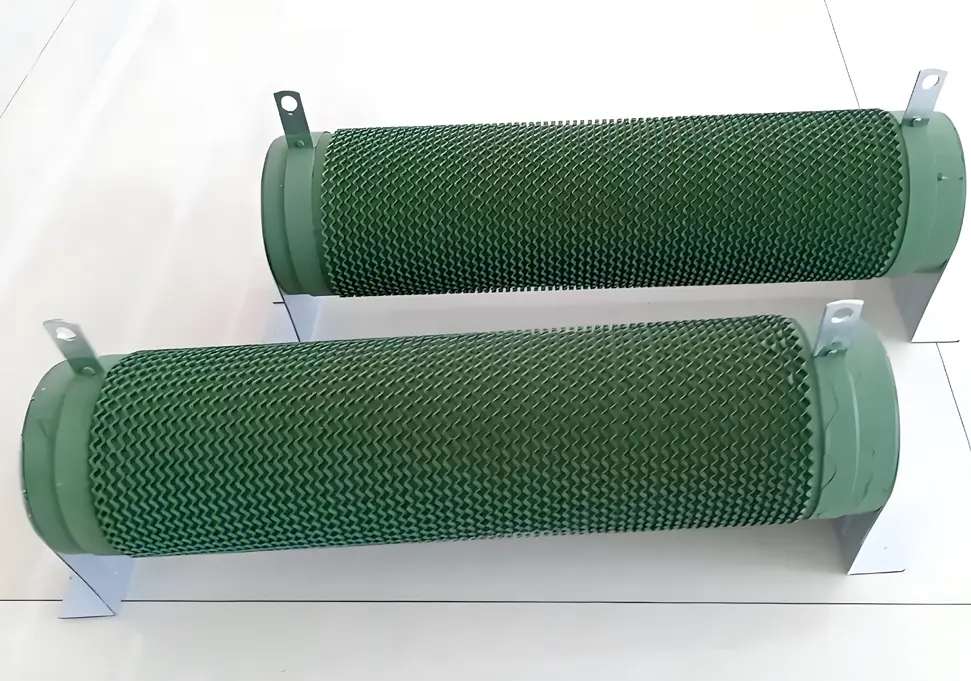

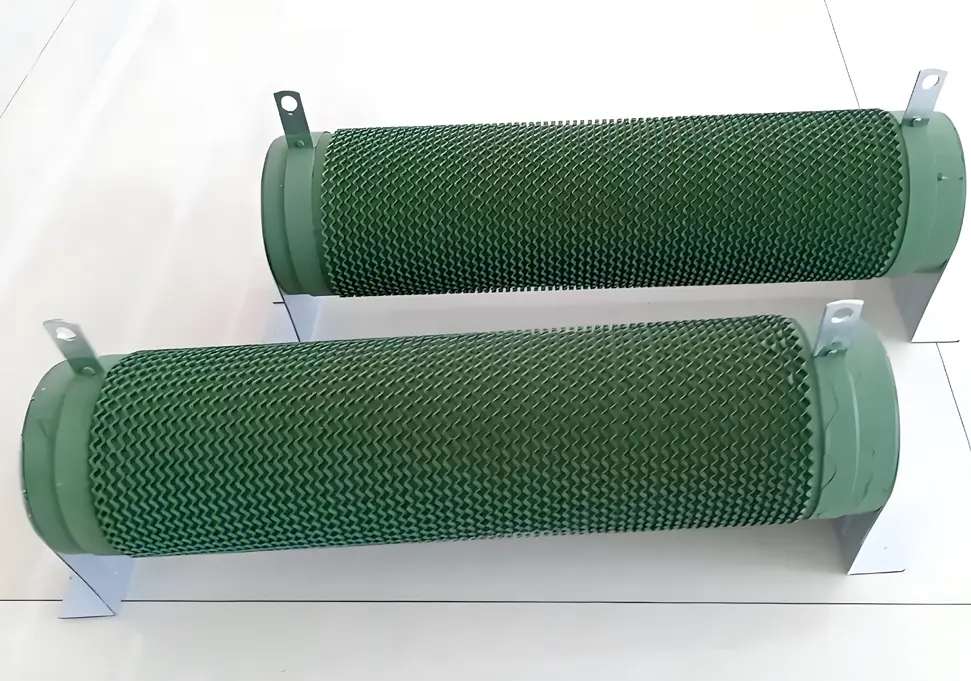

Braking resistors can reach temperatures exceeding 300°C during operation. Always use proper thermal protection and safety barriers.

Ensure proper grounding and follow electrical safety codes. Disconnect power before working on equipment.

Braking system installation should be performed by qualified electrical engineers or technicians.

- Always follow manufacturer’s specifications and guidelines

- Allow appropriate safety margins in component selection

- Regularly inspect and maintain braking systems

- Monitor system performance and adjust as needed

- Document all installations and configurations

Proper selection and installation of VFD braking units and resistors are critical for ensuring reliable and efficient operation of industrial motor control systems. By following the guidelines and calculation methods outlined in this guide, engineers and technicians can make informed decisions that optimize system performance while ensuring safety and reliability.

Remember that each application has unique requirements, and consulting with experienced professionals or manufacturer technical support can provide additional guidance for specific installations.