How to Detect VFD Harmonics?VFD Harmonic Detection Guide: Tools, Process & Standards for Industrial Users

Detecting harmonics generated by Variable Frequency Drives (VFDs) is crucial for ensuring the stability of power grids and the safe operation of motor systems. This process involves selecting appropriate detection tools, formulating scientific testing plans, and analyzing data accurately. Below is a detailed, actionable detection guide tailored to B2B industrial scenarios (e.g., manufacturing plants, water treatment facilities) :

I. Core Detection Tools & Equipment Selection

- Power Quality Analyzers (Primary Tool)

-

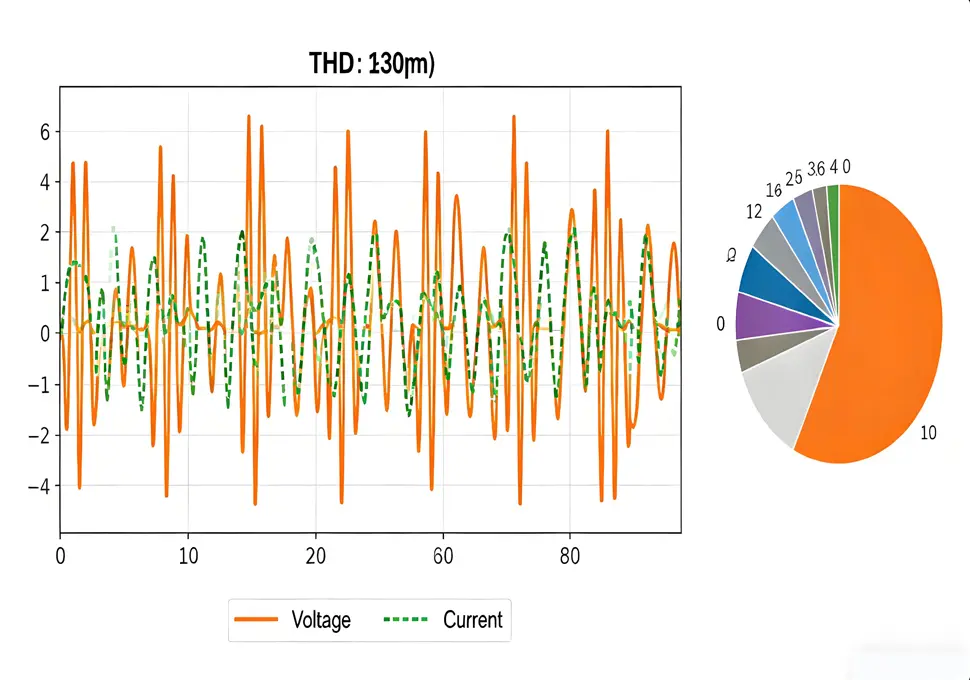

- Function: Professional instruments designed to measure voltage/current harmonics, THD (Total Harmonic Distortion), harmonic orders (up to 50th or 100th), and other key parameters.

-

- Recommended Models: Fluke 438-II, Yokogawa WT1800E, Chauvin Arnoux CA8335 (suitable for industrial environments with high anti-interference requirements).

-

- Application Tips: Choose analyzers with VFD-specific measurement modes to filter out carrier frequency interference and ensure data accuracy.

- Current/Voltage Sensors

-

- Current Sensors: Use clamp-on current transformers (CTs) or Rogowski coils (for large currents) to avoid breaking the circuit. Ensure the sensor’s frequency range covers 50/60Hz (fundamental) to at least 2kHz (high-order harmonics).

-

- Voltage Sensors: Employ voltage dividers or differential probes to measure line voltage, ensuring compatibility with the VFD’s output voltage range (e.g., 380V, 480V).

- Auxiliary Tools

-

- Data loggers: Record harmonic variations over long periods (e.g., 24 hours) to identify peak load harmonic characteristics.

-

- Oscilloscopes: Observe the waveform distortion of voltage/current to visually confirm harmonic presence (suitable for on-site troubleshooting).

II. Step-by-Step Detection Process

- Pre-Detection Preparation

-

- Define Detection Objectives: Clarify whether to measure grid-side harmonics (VFD input terminal) or motor-side harmonics (VFD output terminal), and determine key parameters (THD, individual harmonic order content).

-

- Safety Check: Ensure the VFD is in normal operation, and wear insulated protective equipment (gloves, goggles) to avoid electric shock.

-

- Sensor Installation:

-

-

- Connect current sensors to the VFD’s input/output three-phase lines.

-

-

-

- Connect voltage sensors to the input/output terminals (ensure correct phase sequence to avoid measurement errors).

-

- On-Site Measurement

-

- Parameter Setting: Configure the power quality analyzer to measure harmonic orders (e.g., 1st to 50th), sampling frequency (at least 10 times the maximum harmonic frequency), and recording interval (e.g., 1 second per sample).

-

- Load Condition Simulation: Test under typical operating conditions (e.g., 25%, 50%, 75%, 100% load) to capture harmonic variations across different loads.

-

- Data Recording: Save raw data (voltage/current waveforms, THD values, individual harmonic content) for subsequent analysis.

- Post-Measurement Data Analysis

-

- THD Evaluation: Compare measured THD values with international standards (e.g., IEEE 519-2014, IEC 61000-3-4) to assess compliance. For example:

-

-

- Grid-side THDv (voltage THD) should generally not exceed 5%, and THDi (current THD) should not exceed 15% for industrial users.

-

-

-

- Motor-side THD may be higher due to VFD output characteristics but should be controlled within a range that does not affect motor operation.

-

-

- Individual Harmonic Analysis: Focus on dominant harmonics (e.g., 5th, 7th, 11th, 13th) and check if their content exceeds standard limits.

-

- Trend Analysis: Use data loggers to identify harmonic peaks (e.g., during startup or heavy load) and analyze potential causes (e.g., VFD parameter mismatch, insufficient filtering).

III. Key Notes & Troubleshooting Tips

- Avoid Measurement Interference

-

- Keep sensors away from high-voltage cables and VFD cooling fans to reduce electromagnetic interference.

-

- Use shielded cables for sensor connections to prevent signal distortion.

- Common Measurement Errors & Solutions

-

- Inaccurate THD Values: Check sensor calibration (calibrate annually) and ensure the analyzer’s frequency range matches the harmonic frequency.

-

- Phase Sequence Errors: Recheck voltage/current phase connections to avoid incorrect harmonic phase analysis.

-

- Unstable Data: Extend the sampling time or increase the number of samples to average out random fluctuations.

- Compliance with Industry Standards

-

- Familiarize yourself with regional standards applicable to target markets (e.g., African countries may adopt IEC standards, while South American countries may reference IEEE standards) to ensure test results meet local regulatory requirements.